Mimaki Increases Productivity with New TS330-1600 Dye Sublimation Printer

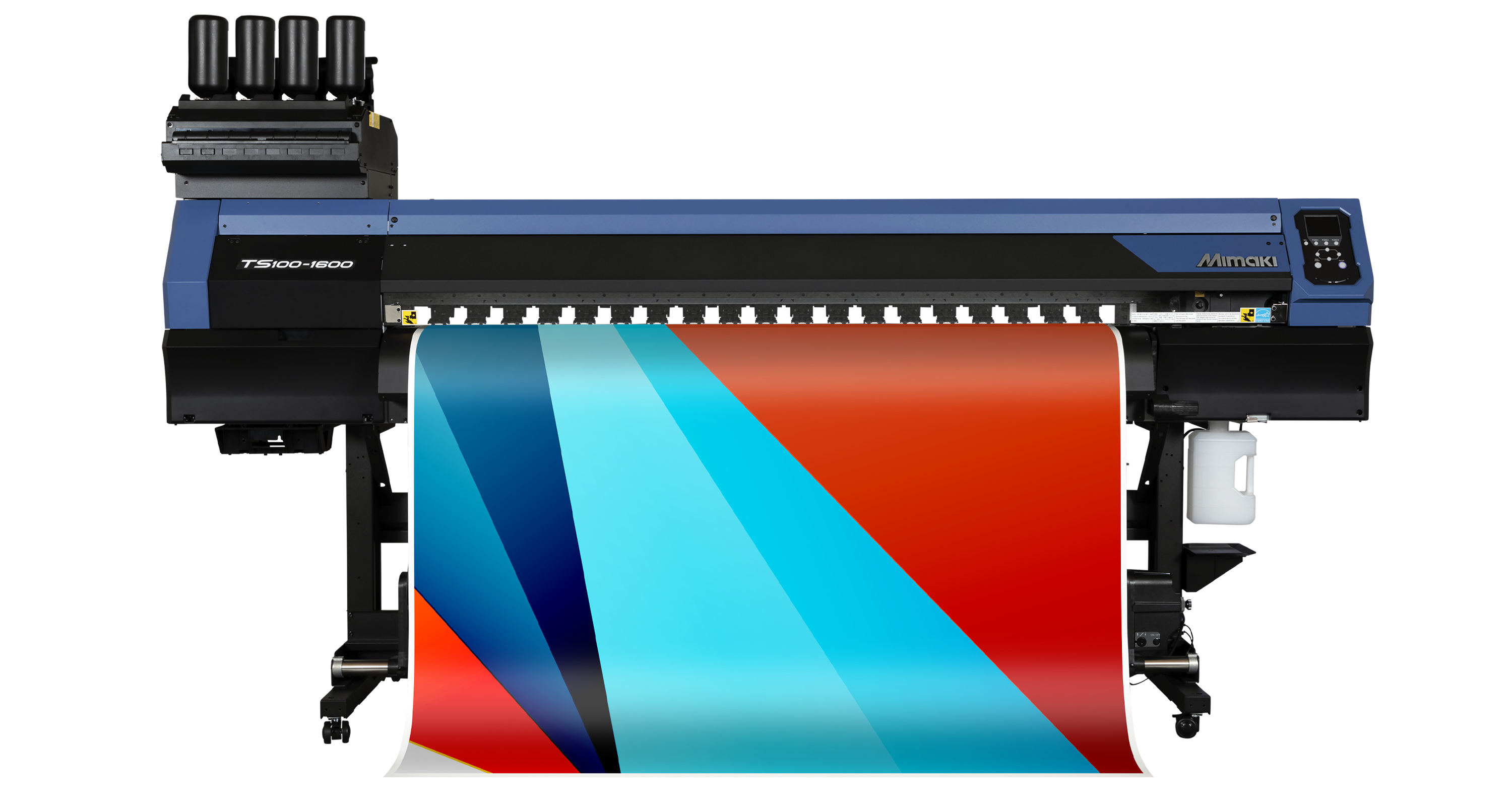

Mimaki has added the TS330-1600 sublimation transfer inkjet printer to its headline ‘330 Series’ platform. Enabling both volume production and high image quality printing for the textile and dye sublimation industry, and equipped with new functions to improve stable operation, the TS330-1600 can achieve a print speed of 69sq m/h in high speed mode, with its fastest mode reaching up to 135sq m/h.

An improved take-up system featuring dual motors distributes the load and increases the power, enabling stable winding of printed paper even for long runs, and new heaters enhance the paper transport through the device. With a retail price of £23,995, which includes Mimaki’s TxLink4 dedicated textile RIP software, along with a standard MBIS bulk ink system, the TS330-1600 has optional add-ons to further increase efficiency. These include a larger 10kg ink tank supply unit which reduces ink costs compared to the standard 2L ink pack and allows for longer continuous printing, as well as a mini jumbo roll unit to load large quantities of transfer paper and further reduce running costs.

The TS330 is one of three models that make up the Mimaki 330 Series, developed to offer mid- to high-end printing models, focusing on premium image quality and high productivity. The 330 Series includes the JV330 solvent printer, the CJV330 printer/cutter and the TS330 dye sub model, and all three feature ‘Mimaki Weaving Dot Technology’ (MWDT), a Core Technology that changes the order of ink droplet placement depending on the printing conditions. ‘Mimaki Remote Access’ (MRA) is also incorporated across the series, improving ease of use by allowing users to remotely access the machine and check the operation status.

The Mimaki TS330-1600 dye sublimation printer is available now through Hybrid’s network of authorised reseller partners.