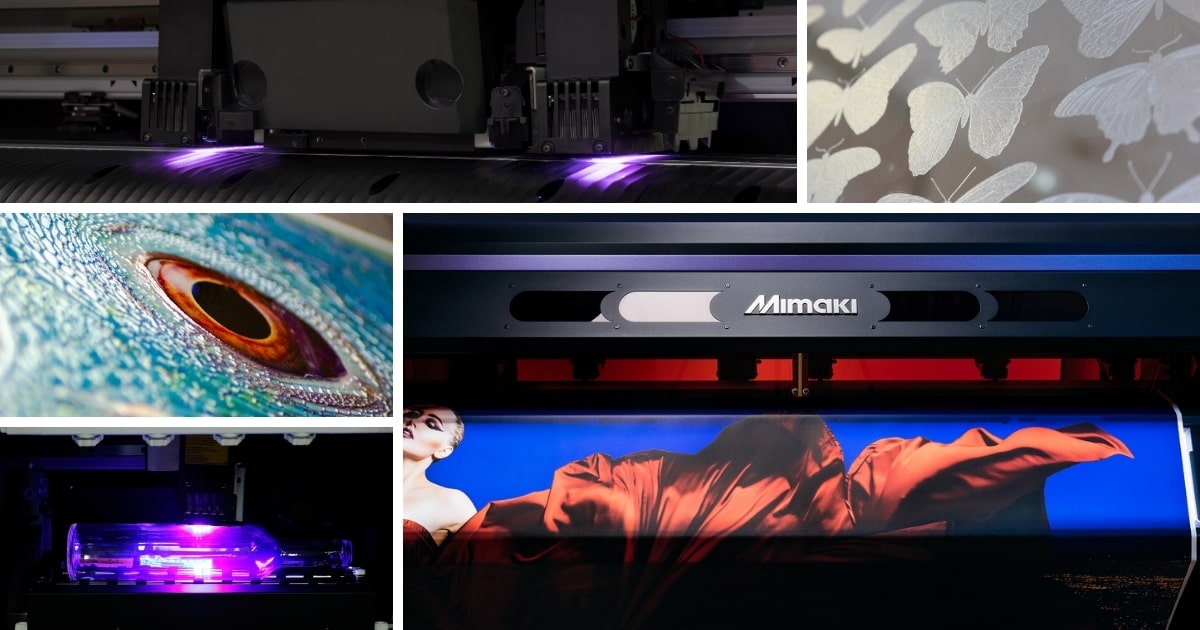

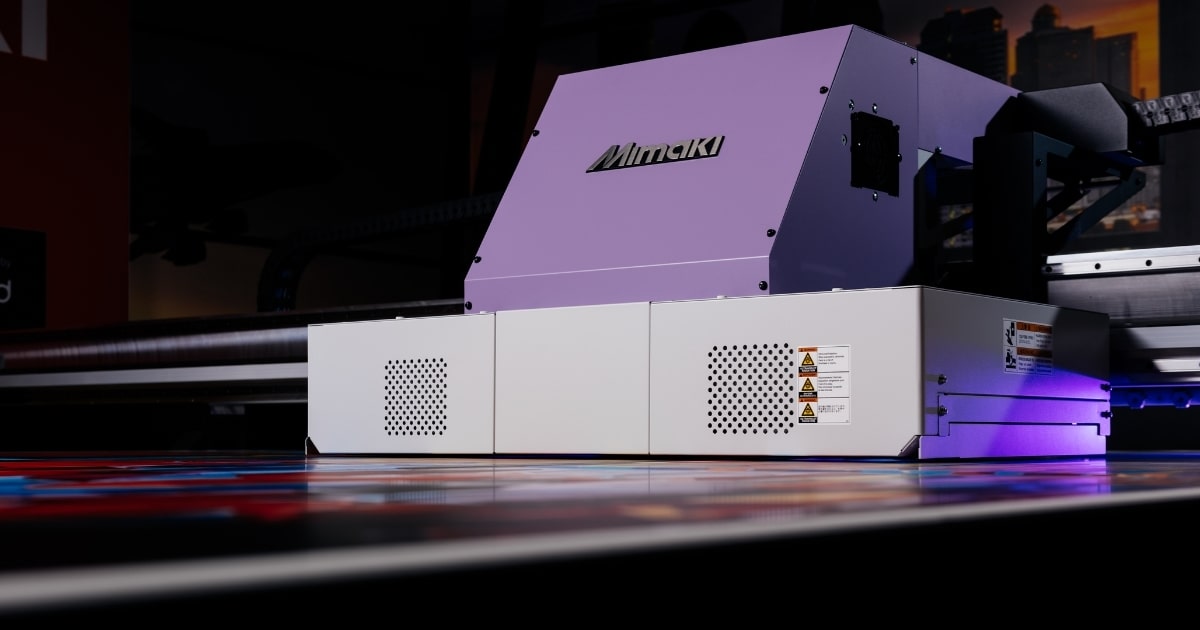

The recent announcement of Mimaki’s two new high-end flatbed LED UV printers has given us something very exciting to look forward to when they land on these shores later in the year, but in the meantime, it’s a great opportunity to reflect on how we’ve got here, through Mimaki’s enviable track record of delivering innovative, large format flatbeds.