Whilst trade printers play a valuable role, investing in hardware for commercial printing in-house has a number of benefits.

Get the latest thoughts and insight from our expert authors.

When producing print for more sensitive user environments, such as the education and healthcare sectors, ink plays a highly important role. Mimaki is a manufacturer committed to developing the most technologically advanced as well as the safest inks and has made an extensive research and development investment over the years to ensure its inks meet the most stringent of environmental and safety criteria.

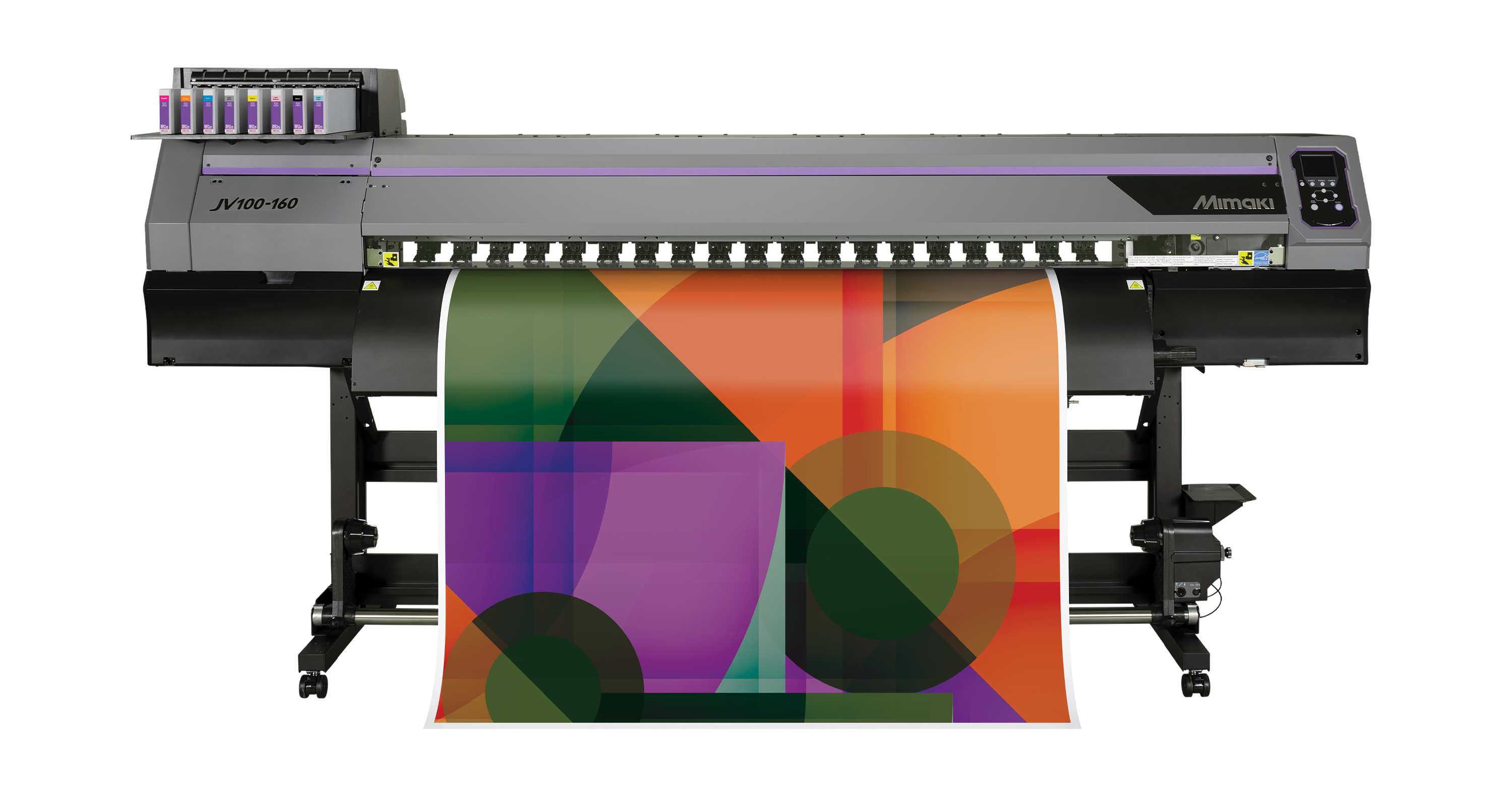

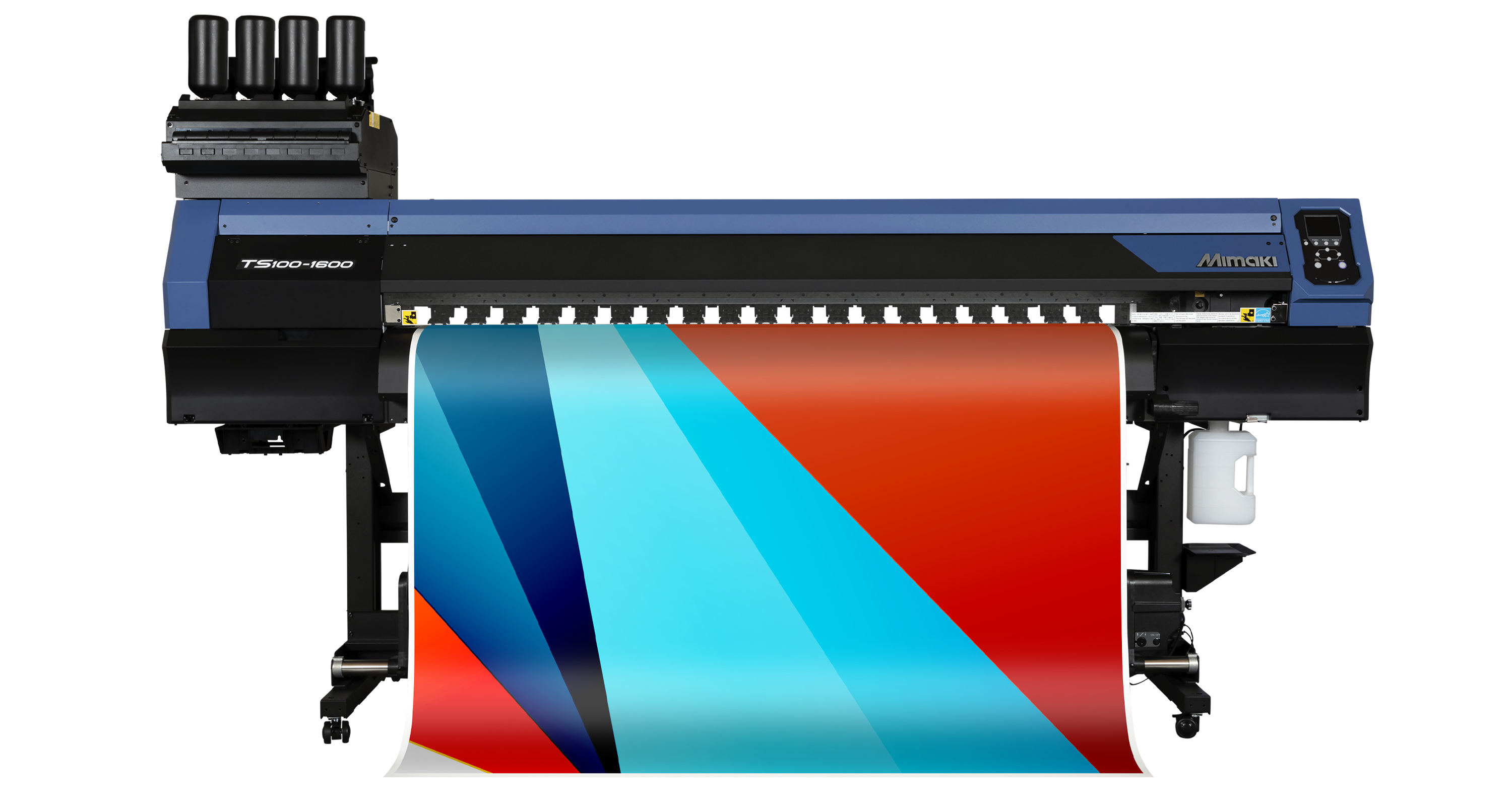

Mimaki’s Core Technologies are specifically engineered to assist print operators in two broad areas; ensuring stable production and delivering high image quality. A series of innovative and proprietary features result in empowering users to deliver unsurpassable image quality – a reputation Mimaki is understandably proud of.