BLOG: How Mimaki’s choice of LED UV ink types can help shape your business

When the time comes to invest in your next LED UV printer, having the opportunity to choose from a broad range of ink types is a critical part of the buying process. Consideration of what you’re really looking to achieve from your hardware investment will help better understand how alternative and additional revenue can be added to your business.

Mimaki’s unrivalled range of LED UV ink consists of a number of options, each with distinct properties and suited to different hardware, either flatbed or roll-to-roll. Benefiting different applications through their varying ranges of flexibility, Mimaki’s LED UV inks suit an almost endless array of end uses, and the first decision to make is whether you’ll need Mimaki’s hard ink or flexible ink.

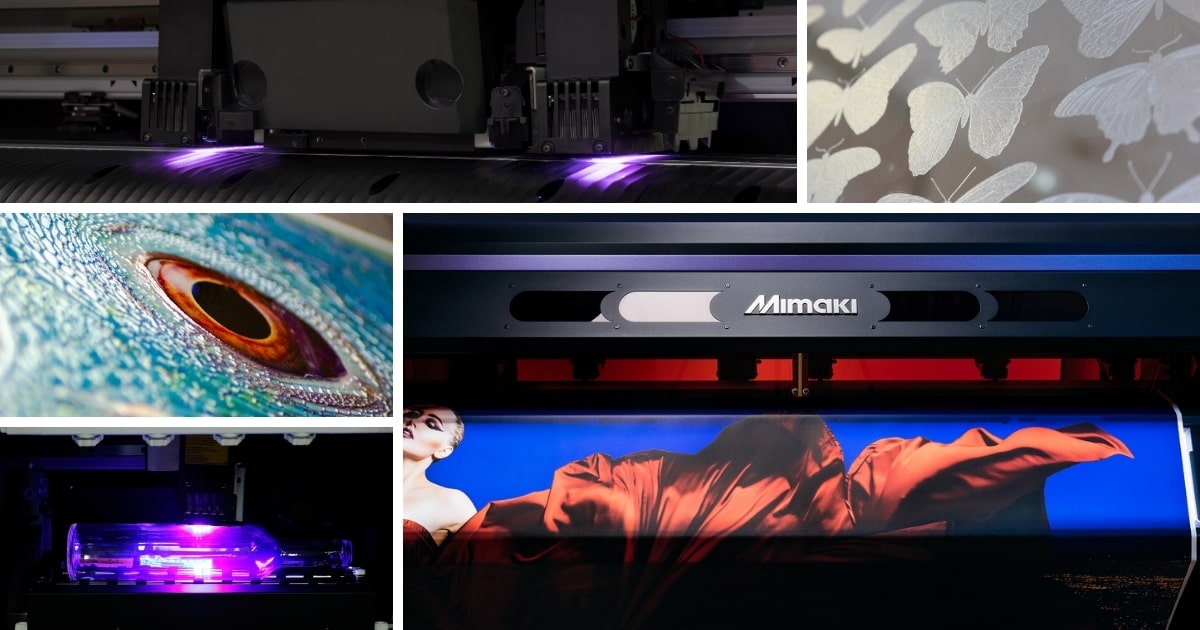

Hard UV inks are tough and ultra-durable. They benefit from great adhesion and are suited to rigid applications such as printing on acrylic, wood, glass and metal. Flexible inks are stretchable to allow for the expansion and contraction of movement and while these will still provide scuff resistance and durability, they’re surprisingly malleable on bendy surfaces like banner, vinyl and flexible phone cases.

For applications such as printing promotional pens, decorative acrylic photo blocks and awards, as well as grand format rigid signage, Mimaki’s LH100 hard inks are ideally suited. Available for all Mimaki’s flatbed LED UV printers, from the A3 UJF-3042FX right up to the 10’ x 5’ JFX500-2131 they provide a long lasting finish on metal, board and other rigid substrates.

In addition to its hard LED UV ink, Mimaki has an expanding number of flexible options too. These range from inks that offer small amounts of stretch, to assist with applications such as packaging proofing – where creasing, scoring and folding could, with a hard digital ink or traditional screen print ink, potentially lead to the print lifting, flaking or shattering, right up to inks that can stretch to over 3 times their original proportions making them perfect for prints that can be vacuum formed. This involves printing onto a substrate such as a thermoplastic which when heated and pressed over a mould, can be shaped into a 3D object.

More typically though, having an ink that not only stretches around corners but that adheres to challenging substrates is enough for almost any print application. Adhesion can be increased in materials that possess low surface energies by pre-treatment technologies such as primers. Mimaki GM1 for glass and metal is a hand-applied primer that gives an extra boost of adhesion, and to automate the process, Mimaki has also developed two printable primers: PR100 for rigid applications, and PR200 for use with flexible inks, opening up an even greater choice of new materials and objects that can be printed to.

Finally, by incorporating Mimaki’s clear varnish, it’s possible to highlight areas with spot or flood coating, as well as to deliver embossing opportunities with multiple passes. Available for Mimaki’s LED UV flatbed technology since 2016, and now useable in the UCJV300 series roll-to-roll printer/cutter and new UJV100 roll-to-toll printer, the development of clear UV cure ink has created a wealth of design possibilities and expands business opportunities by creating compelling displays using gloss, matte or textured finish.

So, when the time’s right, we’re here to help you investigate all the options, gain a better understanding of what you’re able to produce and which of Mimaki’s many LED UV solutions will be most appropriate for your business. Please get in touch with the Hybrid team and we’ll be happy to assist.