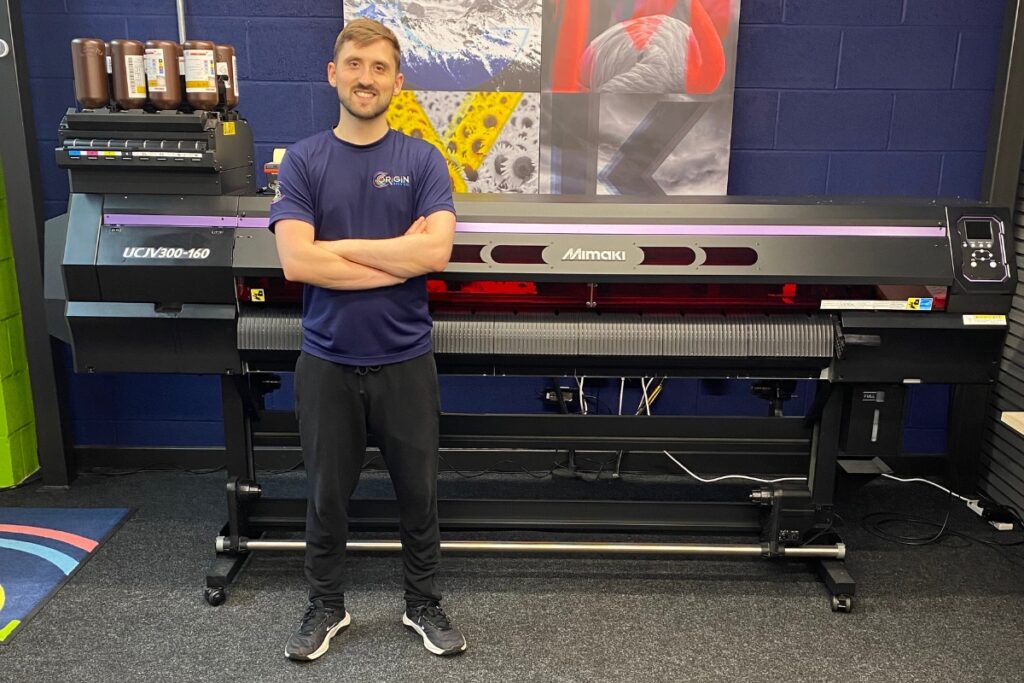

Origin Sign Co enters new markets with Mimaki UV technology

Two Mimaki industrial UV printers sit at the heart of Skelmersdale-based sign maker, Origin Sign Co’s kit list and are allowing the forward-thinking business to target new markets as it expands its operation with new applications and products.

Key to Origin’s expansion is its multi-award winning Mimaki JFX200-2513EX – an 8’ x 4’ flatbed LED UV printer that is used for direct to substrate printing when creating site boards, hoardings and further, more creative applications. “The quality of the Mimaki JFX200 is outstanding,” Digital Print Manager, Joe Clark notes. “It’s given us that level of consistency that’s so important to the business.”

The Mimaki JFX200-2513EX UV printer delivers high quality output, utilising a broad choice of instantly cured LED UV inks including white and clear, and an 8’ x 4’ bed size that suits industry standard boards and substrates. Capable of producing high volumes of print, it offers best in class performance coupled with impressive levels of creativity.

Mimaki JFX200 adds multiples efficiencies

With its ability to print direct to acrylic, aluminium, foamboard and multiple other rigid materials, Origin has also benefited from the quality of the white ink, that’s a key element in the company’s more creative offerings. “When we’re producing reverse prints on clear acrylic, the white ink is flawless,” Clark explains. “And it’s not just the print quality we’re benefiting from – in terms of efficiency, the JFX200 has really helped the business.”

Allowing the team in the company’s recently refurbished print operations room to cut out processes by printing direct to rigid materials, the Mimaki JFX200 is helping Origin save both time and media. The impact it’s having on their eco footprint is a significant gain too. Drawing minimal power thanks to its cold cure LED lamps, the energy efficient flatbed is helping the company hit its sustainability goals. “As a business, we’re making a conscious effort to operate more sustainably,” says Production & Fabrication Manager, James Watterson. “From using offcuts of material to running energy efficient machines like the Mimaki UV printers, we’re keen to demonstrate to our customers that we have that edge.”

Origin is also working hard to develop its customer base, targeting new sectors with its range of printed and manufactured signage. “Whilst our core business is in the construction industry, we’re making great progress with new markets like holiday parks and care homes, with clients seeing real advantage in our bespoke approach to their signage requirements,” Clark confirms.

The company invested in its Mimaki printers from authorised reseller partner, I-Sub Digital, as Watterson recollects. “We found their training to be really helpful. On the same day as the machines were installed, we were printing work, and the quality was outstanding from the get-go.”

Origin also benefited from the software that’s included with the Mimaki printers. “The Mimaki RasterLink RIP supplied with the JFX200 changed the way we operate,” recalls Clark. “It’s so much easier to print multi-layer designs, being more intuitive and user-friendly.”

User friendly solutions

In addition to their Mimaki flatbed, the company’s trusty UCJV300-160 wide format LED UV printer/cutter plays an important role in Origin offering a diverse range of products, with punchy graphics reproduced on premium metallic films and window media thanks to its white ink and clear printing capabilities. “The Mimaki hardware is so user-friendly,” summarises Watterson. “It’s easy to use and maintain, and rewards you with great results every time. It’s all you can ask of it.”

The Origin Sign Co team have taken to social media to attract new clients and assist their current customers with entertaining and informative posts that promote the business to a growing audience. Follow their adventures on Instagram and TikTok – and pick up some design and sign making tips along the way.