Printing Leather Using A Mimaki

The challenge of producing a high quality print to leather became something of a ‘pet project’ for Magnus Mighall – partner at long standing Mimaki reseller, R A Smart.

With other print companies digitally printing leather using the dye sublimation or solvent route with some degree of success, he felt sure there was a better way to marry up the advantages of a digital print with the potential for a premium end product manufactured from leather.

With an impressive heritage in high end textile printer and having trialled existing digital techniques, he very much stumbled upon a process using Mimaki acid inks – an aqueous formulation – printing direct to either vegetable, or the more supple chromium tanned leather. R A Smart is not only a digital printer reseller – they have a notable printing setup themselves, including in their roster a substantial digital capability alongside an established flatbed silk screen setup – plus weaving and screen making functions too.

One of Mighall’s first attempts was to try screen printing the leather with their acid inks – more typically used for achieving high end results onto silk, nylon and wool, but the various other elements of the ink chemistry were ‘getting in the way’ of the dye’s ability to key to the hide.

The beauty of digitally jetting acid (and other textile) inks, is that the binder and other aspects of the chemistry are present in the pre-coating of the fabric, so what is actually jetted is almost pure dye. Finding spectacular success using this route was something of an eureka moment for the company, with not only deep, rich and vibrant colours achievable but also excellent rub fastness and print consistency.

Whilst R A Smart has had great success using a combination of the Mimaki TX2 and Mimaki’s acid inkset, Mighall is quick to stress the importance of testing everything beforehand. “You’re dealing with a very variable substrate,” he says, “and whilst that’s the beauty of the leather itself, the end application needs to be considered in the testing to ensure that rub fastness and colour consistency is as expected.”

The company is able to produce high end gifts, belts, wallets, folios and phone covers, and it’s this sort of application that Mighall feels is best suited to the process. “Small accessories are the perfect product to create digitally,” he notes. “A premium product can be created but it’s quite a labour intensive process, so the payback needs to represent this.”

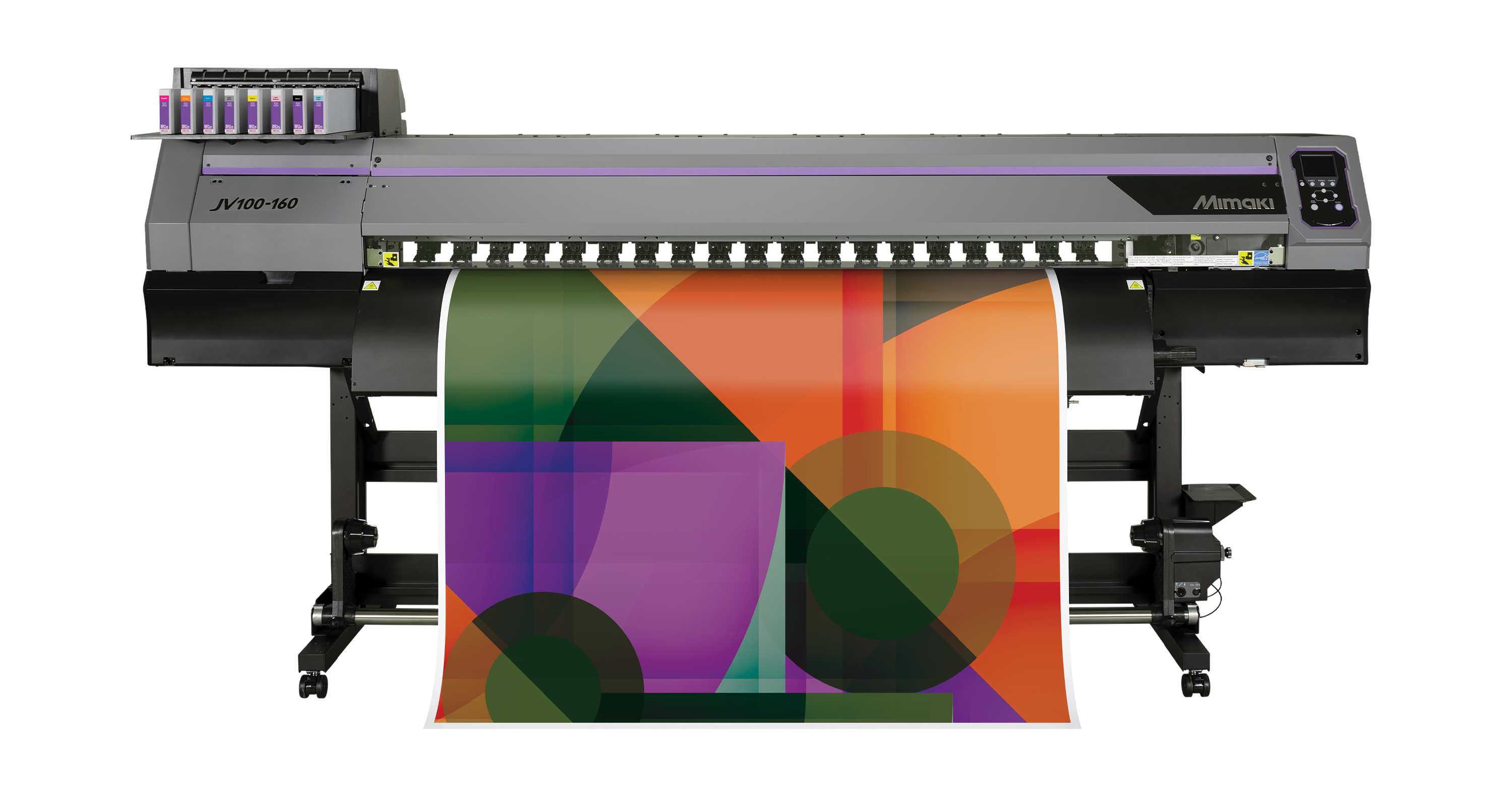

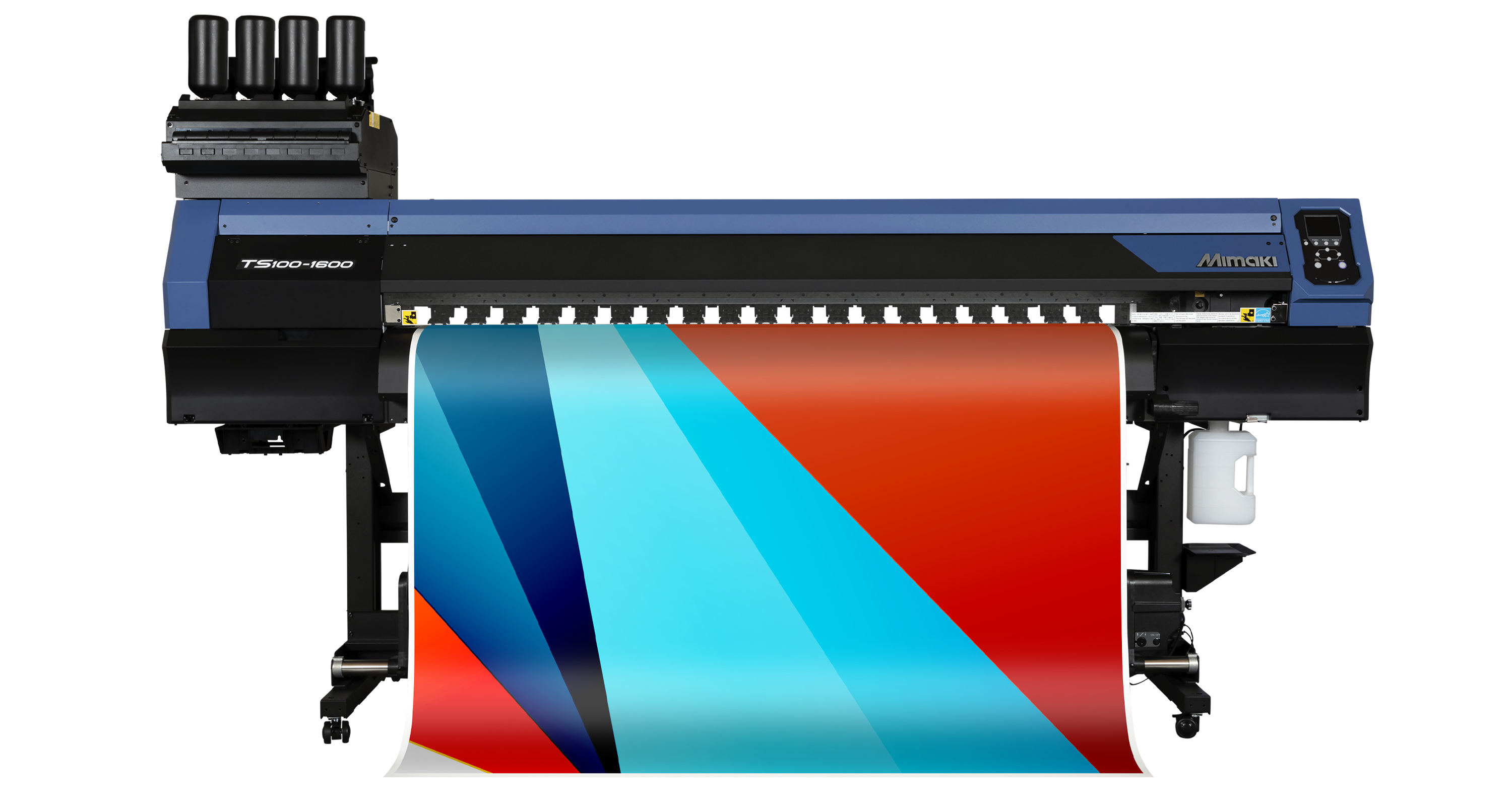

R A Smart has their hides cut square, and in cases such as their Masonic lambs leather, dyed white to deliver the best colour yield. The hide is then affixed to a board to ensure consistent carriage through the printer, and Mighall’s preferred machine is the 1.6m wide Mimaki TX2. “The adjustable head height on the TX2 allows us to run the combination of board and 3mm thick leather through the machine, and the flexibility of the printer is a bonus too.”

“In addition to leather printing, it’s possible to use the acid inks for their more typical application of silk printing. Of course the TX2 can have two different ink types installed as well, so if users want the ultimate flexibility, there’s nothing to stop them running a dye sub inkset in one bank of heads and opening up all the opportunities of printing to polyester or transfer paper as well.”

This kind of intensive R & D is nothing new to the company. As one of the first digital textile printing companies in the UK, it’s often that they find themselves breaking new ground and pursuing interesting (and hopefully profitable) new revenue streams but it’s all in a days work for Mighall. “The benefits of trying new projects are in finding success such as the leather application. It brings new companies to the printing arena, gives us another string to our bow and delivers yet another series of products that can be produced with the digital model,” he concludes.