Loop Print stays one step ahead of the competition

With over half a century of experience, Loop Print Limited is a company that strives to be one step ahead of the competition, being fully committed to innovative printing techniques. When they met specialist Mimaki reseller, Sabur Digital at the Sign & Digital UK 2018 Exhibition at the NEC in April earlier this year it was to be the start of a fruitful working relationship, as Sabur’s Joe Preddy explains;

“We had a big presence at the exhibition and Chris Gray, the MD at Loop came along and explained about his company, what their needs were and what he felt was needed to improve production in this part of their company.”

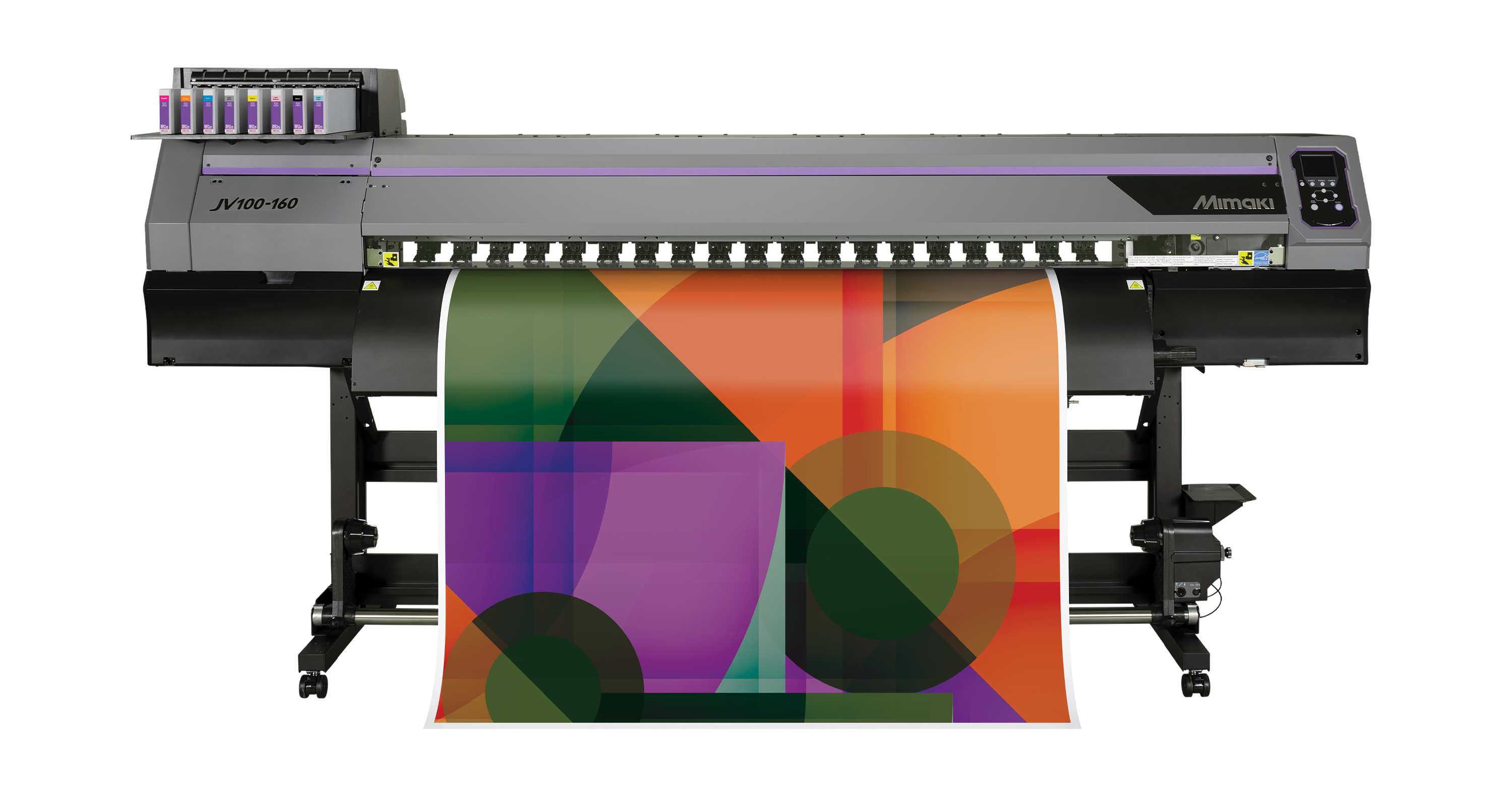

“He mentioned that he printed a lot of POS posters and with his current Eco solvent wide format printer he would have to wait twenty hours for the prints to gas off and dry before being able to trim and finish them,” continues Preddy. “This was causing an issue on short turn-around jobs that are so common in a fast-paced printing industry. Loop Print produce litho, digital and large format work with a full complement of finishing equipment and full in-house design studio. Their core services are general commercial print, but with a heavy nod towards producing top end work and work that is not easily achievable at a conventional printers.”

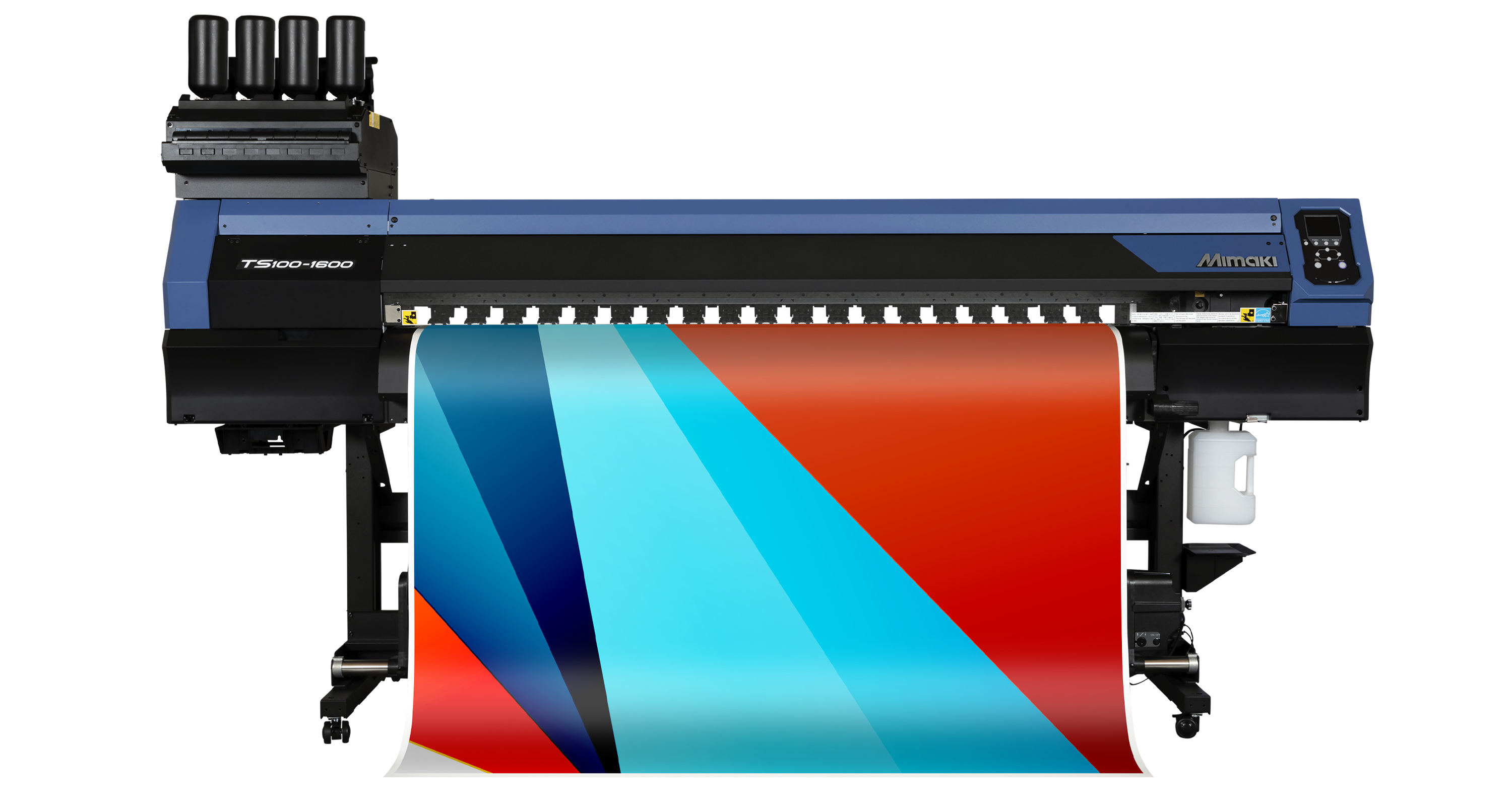

Loop Print attended Sabur Digital for a demonstration on the new Mimaki UCJV300-160 roll-to-roll LED UV printer/cutter that’s revolutionising the sign and graphics market, as Preddy goes on to say; “I think it’s fair to say that they were blown away by the quality it produced. Not only did it come off dry, it also had an increased scratch-resistant finish, allowing them to re-evaluate the need to laminate everything.”

From very humble beginnings, Loop Print Limited have gone through over fifty years of continual growth, change, and diversification. Today, they are based in modern 16,000 sq ft premises in Sheffield, servicing a huge spectrum of businesses in the creative and advertising sector and beyond.

A few years ago, Loop Print invested in a H-UV litho press to differentiate them from the competition. Apart from sheets coming off the press immediately ready for post press operations, it allows the company to print on a range of substrates and gauges including plastics, PVC and polypropylene that are simply not an option for most printers.

Loop Print’s Managing Director, Chris Gray discusses why the Mimaki UCJV300-160 caught his eye; “We spotted straight away that at 1600mm wide, the UCJV300-160 would not only take the place of our solvent printer but also our flatbed printer too, and all the issues and problems that came with that machine.”

The beauty of UV-LED is that instant drying allows jobs to be left running on the take-up roller without potential problems of gassing and spoilage due to sticking and set off. “The quality of reproduction is quite superb and the stability of the ink on the substrate is totally bullet proof,” continues Gray. “Using white on a conventional solvent machine has in the past been hard work because of the ink composition. With the UV-LED inks that problem has gone.”