Double Mimaki textile printer launch responds to changing industry demands

Mimaki’s distributor for the UK and Ireland, Hybrid Services has today announced the addition of two new high performance textile printers to its market-leading product portfolio – the Mimaki TS100-1600 and the Mimaki Tiger-1800B MkIII Printer.

Add digital print technology to meet changing market demands

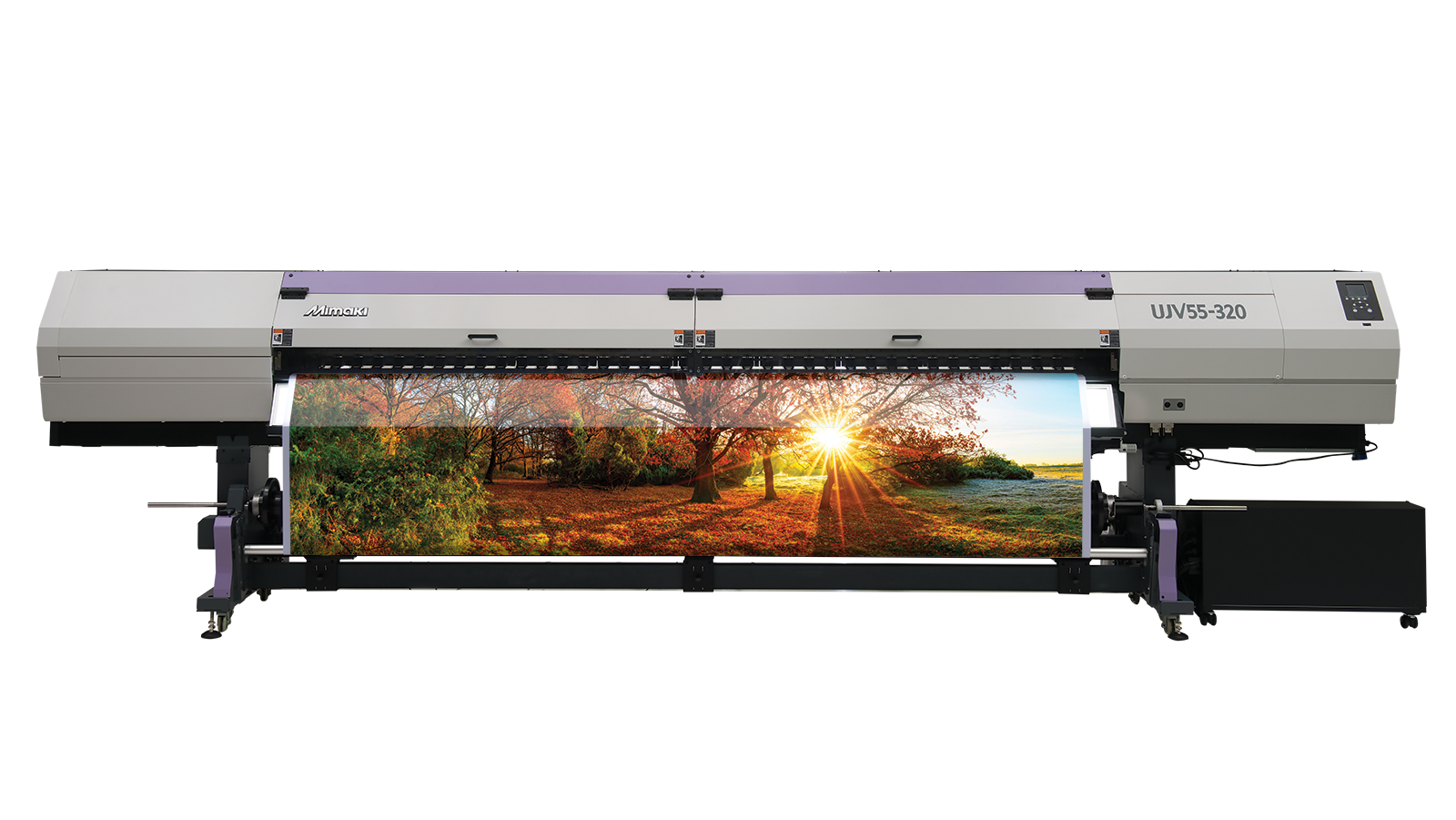

The TS100-1600 is Mimaki’s latest addition to its ‘100 series’ portfolio, with this affordable, high-quality system positioned as ideal for printers looking to add their first digital sublimation printing solution or expand their production capacity. “The opportunity for printers to adopt dye sub printing is significant,” states Hybrid’s Managing Director, Brett Newman. “With an increase in demand for personalisation, bespoke prints and custom décor, the new TS100-1600 offers companies a low cost route into this proven technology.”

Available from April 2021, the new TS100-1600 has a print width of 1,600mm and speed of 70m2/h in its fastest mode. In addition, the use of 1 litre ink bottles helps reduce the running cost and enables stable, continuous operation due to the reduced need for ink replacement. The printer is also equipped with a variety of renowned Mimaki technologies, including NCU (Nozzle Check Unit), NRS (Nozzle Recovery System), and DAS (Dot Adjustment System) function which automates dot position correction and feeding amount correction, reducing the need for operator intervention. While Mimaki’s RasterLink 7 RIP software is supplied as standard, printers purchasing the TS100-1600 can also choose to add TxLink4, an alternative Mimaki original RIP software platform.

Bert Benckhuysen, Senior Product Manager at Mimaki Europe explains further, “The textile printing industry has seen a growing requirement for increased product variety, lower inventories and shorter delivery times. Add to that the economic challenges of 2020 and we recognised that the market needed a digital textile printer that combined high quality, on-demand output with a low initial investment and cost-effective production. Having seen the success of our 100 series printers for the same reasons in other sectors, we knew that introducing a textile printer to this range would provide our customers with an opportunity to expand their businesses and seek new revenue opportunities, even amid these challenging times.”

Get ahead of the competition with the new and improved Tiger-1800B MkIII

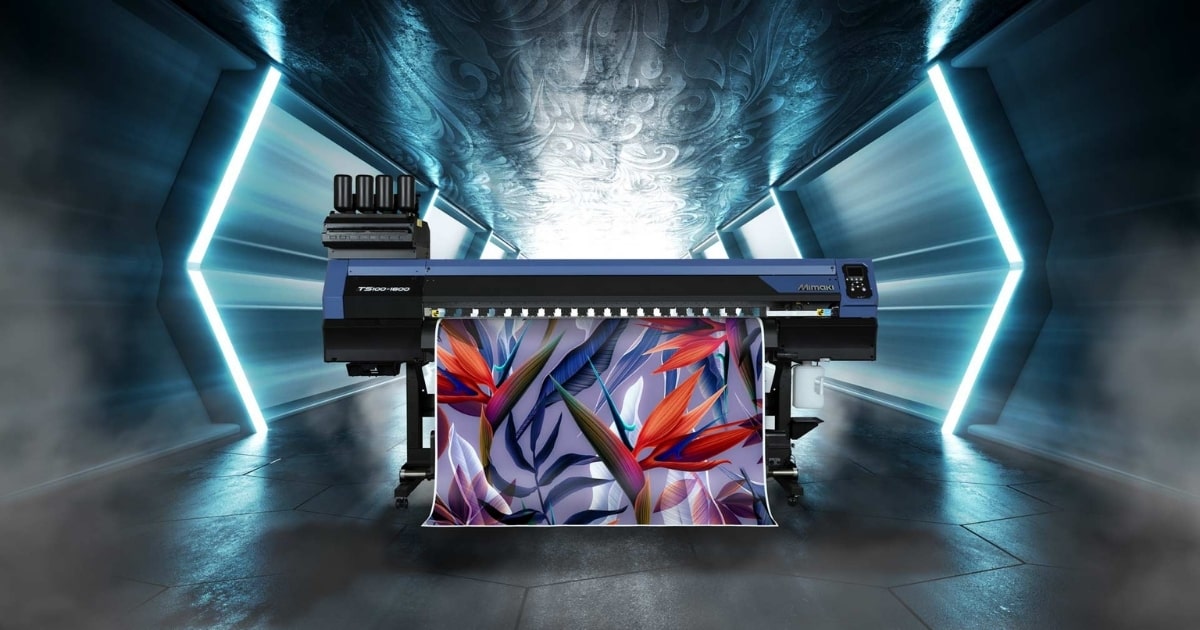

The second new printer announced is the Tiger-1800B MkIII – the latest model of this high-speed, high-volume industrial textile printer range. Available as a high-quality direct-to-textile (reactive or direct sublimation) or sublimation transfer printing solution, the new Tiger-1800B MkIII has been developed with reliability and print accuracy at the forefront of the design process and features new software capabilities that help to increase productivity and reduce downtime.

“The textile industry is fast-moving, highly creative and leaves little room for error,” continues Benckhuysen. “Printers in this market require a robust system that will deliver the speed, quality and innovation needed to keep pace with this exciting industry. The new capabilities of the Tiger-1800B MkIII build on those featured in successful predecessor models to meet these requirements head on.”

The new features of the Tiger-1800B MkIII include the ‘Mimaki Printer Controller’ (MPC) software which has been designed for ease-of-use and enables users to set up, operate and output data with one-touch, simple operation. Its intuitive interface and functionality allow users to easily run automated overnight operation by sending multiple jobs with different settings to the print queue. The nozzle recovery function further reduces downtime by allowing production to continue if the printer encounters a nozzle malfunction.

The Tiger-1800B MkIII is also supported by the latest ‘TxLink4’ software. Its new ‘Parallel RIP function’ can manage multiple sets of print data at once to maximise productivity and the ‘Variable print function’ provides printers with the flexibility to produce more innovative, creative apparel applications. This latest system has also been upgraded with 16-bit rendering to enable a smoother gradation expression and can handle high-speed data transfer thanks to its 10 GB-based Ethernet controller.

“The launch of these two important textile printers confirms Mimaki’s significant and ongoing commitment to delivering cutting edge fabric printing solutions that respond to specific demands within our industry,” Newman concludes. “With such a variety of options across the Mimaki range, we are in an enviable position to assist companies as they invest in new opportunities, increase capacity or simply seek to meet the specific needs of their business.”