Mimaki to Spotlight Latest Sustainable Solution at Heimtextil 2025

Mimaki Europe has announced its attendance at global textile tradeshow, Heimtextil 2025 (Frankfurt, January 14th-17th). The show, as the world’s largest trade fair for home and contract textiles, will give Mimaki the opportunity to demonstrate its latest sustainable innovation, TRAPIS, at its booth in Hall 3.0 Stand B96.

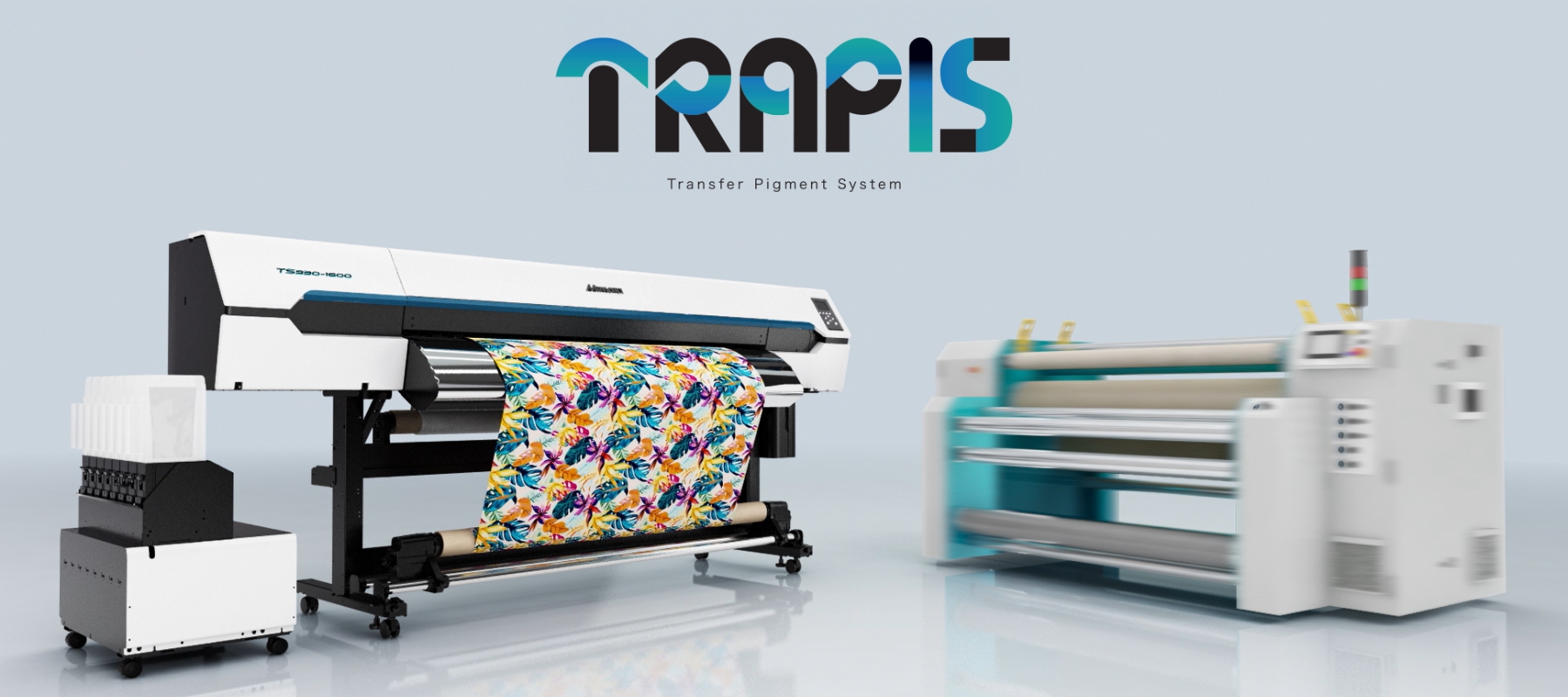

Following the system’s commercial launch earlier this year, TRAPIS is set to revolutionise the home textile industry with its environmentally friendly two-step textile pigment transfer printing process. By eliminating the need for pre-treatment and washing stages, TRAPIS reduces water usage by up to 90%, saving approximately 14.5 litres per square meter compared to traditional methods. This nearly waterless solution is ideal for diverse applications, such as home textiles, as it enables vibrant printing on a diverse range of materials – including natural fibres, blends, and synthetics – with a single ink type. Certified by ZDHC MRSL Lv.3 and carrying the bluesign® APPROVED label, the ink ensures both environmental and user safety, making TRAPIS a safe, eco-friendly solution for textile applications in sectors such as home décor, activewear, and fashion.

TRAPIS also streamlines production with its simplicity, requiring only an inkjet printer and a high-pressure calender, making high-quality, sustainable textile printing more accessible to print service providers worldwide. Its compact size allows for installation in limited spaces, such as the front of a print shop, and eliminates the need for costly wastewater treatment facilities. Additionally, the solution is easy to operate, requiring no specialised skills or complex maintenance and adapts to customer demands, even for short multi-material runs, while maintaining high standards for safety, colourfastness, stretchability, and breathability.

Taking TRAPIS on the Road

Following the system’s announcement earlier this year, Heimtextil will serve as a stop on Mimaki’s global TRAPIS Roadshow, launched in Amsterdam with the Mimaki’s Textile Day Open House on 27th November. Each stop will demonstrate TRAPIS to a different regional market, offering hands-on experience with the new solution and showcasing Mimaki’s innovation in the textile sector. The roadshow will continue into 2025, stopping in countries such as the UK, Poland and Spain, with more to be announced in the coming year.

“UK customers eager to be among the first to see the revolutionary TRAPIS system can visit Hybrid on 29th and 30th January. Scheduled presentations of the technology will take place throughout the day, offering visitors the opportunity to explore it alongside Mimaki’s other complementary textile technologies, including DTF, dye sublimation, and direct-to-textile solutions,” says Hybrid’s sales director, Andy Gregory.

Marc Verbeem, Product Management Supervisor, Mimaki Europe, comments, “As a global hub for innovation and creativity in the home textile industry, Heimtextil presents us with an opportunity to showcase TRAPIS. This technology not only simplifies production but also significantly reduces environmental impact, addressing the evolving demands of the industry. We look forward to engaging with the textile sector and demonstrating how TRAPIS can achieve vibrant, high-quality prints on a wide range of materials while prioritising sustainability.”