New Mimaki SUV Delievers Competitive Edge For Harrisons Signs

York-based Harrisons Signs has been manufacturing signage since the early 1900s and currently offers a broad range of services including interior and exterior signage solutions, exhibition graphics and vehicle liveries.

In order to support future growth and meet increasing customer demand for fast turnaround jobs, the firm recently made the decision to invest in a new Mimaki SUV wide format printer to optimise workflow and productivity.

Having used Mimaki printers since the early years of this century (a JV3 followed by a JV33 that is still providing great service) Peter Robinson of Harrisons Signs accepted an invitation to test drive the latest technology in a reseller’s demonstration suite. Of particular interest was the instantly dry prints delivered by the new printer. The sheer quality of the output from the Mimaki SUV, coupled with their experience of the brand, saw an order placed on the day.

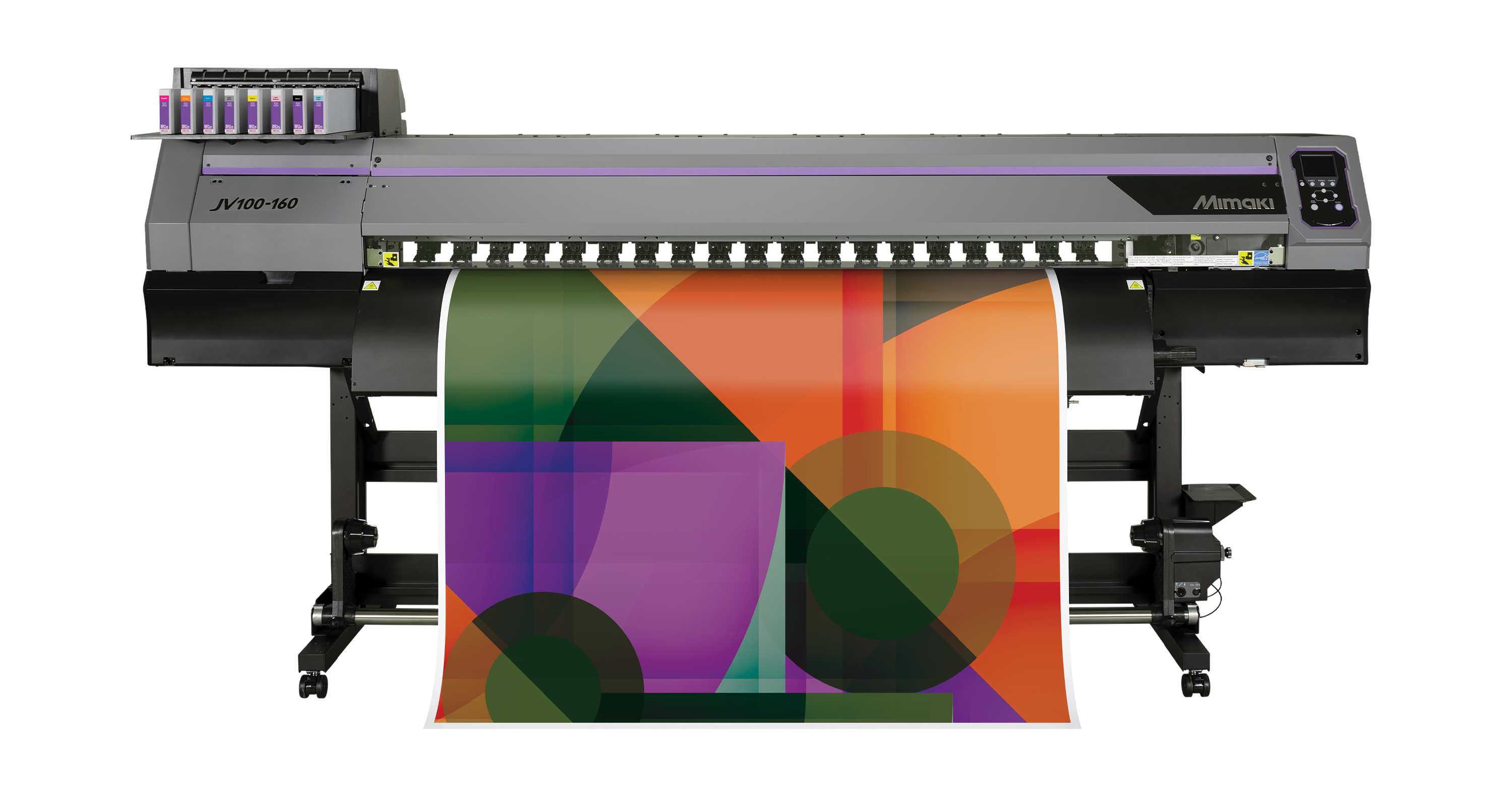

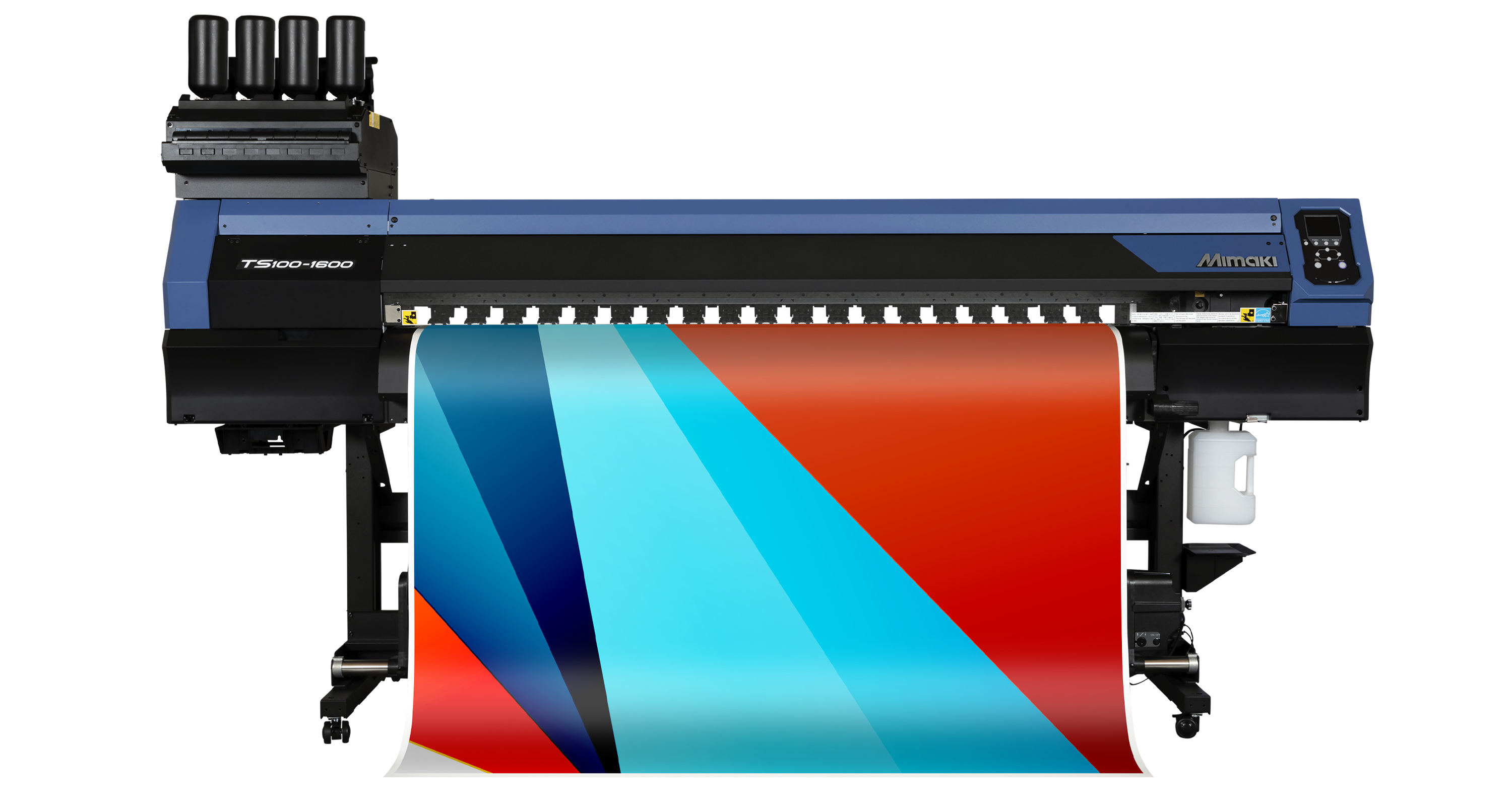

The Mimaki SUV is the latest in a long line-up of high end wide format printers from the innovative Japanese manufacturer and sports a photo quality print engine capable of producing an outdoor durable print onto a wide range of substrates. It features a unique glossy finish that is extremely durable and can be cut, applied and packed as soon as it leaves the printer. Available in 1.3m or 1.6m print widths, it is supplied with Mimaki’s pro level RIP software and a comprehensive Gold warranty. Part of Mimaki’s ‘eco’ range, it sits comfortably in an office environment and only requires standard 240v power.

Offering something different

Robinson explained: “We’d initially looked at other ink technologies to sit alongside our JV33, but the SUV clearly offered something different that we could pass onto our customers.

“With our current high workload, we were starting to see production bottle necks which we were keen to eliminate. Ease of use of the new machine was a key factor in our purchase decision, with similar technology and interface to existing machines, coupled with valuable onsite training from PaperlinX, the transition was virtually seamless and delivered almost immediate production benefits,” he said.

Continued investment in new technology has consistently stood Harrisons Signs in good stead, but in testing economic times, Robinson was all too aware of the need to make the right decision. “Reducing business operating costs is critical – without compromising quality. The potential for cost and efficiency savings in all areas of production was one of the main reasons for our investment in the new Mimaki and whilst the new machine has only been in use for a couple of months, we are already reaping the rewards and expect a very early return on investment.”

Seeing advantages in its instantly dry print, Harrisons has been able to dramatically cut its total job time, “The speed of the whole job is an essential real-world calculation,” he said. “We’ve got new found flexibility. Much of the time, we’re cutting out post-print processes such as laminating which makes us more competitive and efficient. For example, whilst a 30m print run might previously have taken as long as 4½ hours to output, the new SUV reduces this to around 3 – 3 ½ hours, representing an efficiency gain of around 25%, bringing huge benefits to the customer and the business.”

New products for high profile clients

The 17-strong team at Harrisons Signs features designers, printers, fabricators and a strong crew on the road, capable of installing jobs for a vast range of clients, across the length and breadth of the country. According to Robinson signage is a large umbrella of products and one which the company is looking to enlarge with its latest investment.

“We’ve got new products coming off the Mimaki SUV such as 1.5m pull-up banners. We don’t need to laminate it because of the toughness of the inks; the colours jump off the media and it’s quick to produce. In addition, without the need for drying or degassing of the print output, it gets trimmed and fitted into the cartridge, the instant it comes off the printer,” he said.

Perfection through innovation

Working with high profile retail clients is proving an enticing area for Harrisons Signs – giving the company an opportunity to test its new kit. An in-store product promotion for a coffee manufacturer required 30+ metres of printed self-adhesive vinyl applied to foam board and Robinson jumped at the chance of running it on the new SUV. “The high gloss finish suited the agency’s requirements perfectly and with the client demanding very high image quality we felt confident in using the new SUV printer.”

Feedback has been excellent with happy customers all round. “Removing the need for lamination has reduced labour costs and kept us competitive, and we were able to install well inside their deadline, by mounting the graphic to the board within minutes of it leaving the printer,” he added.

Looking forwards, Robinson sees only one direction. “Our past is important, but we’re always looking ahead. We have future plans to expand our metal fabrication, which sits well with our more traditional products; a combination which sets us apart.”