Why are UV Inks so popular

Over the last few years, UV ink applications have become increasingly popular due to a number of reasons.

Firstly, the increase in hardware utilising LED UV curing technology has proven popular due to its green credentials, cost saving benefits from reduced running costs and lack of heat opening up a whole host of heat sensitive media to be printed onto. UV inks give excellent adhesion, especially when used with a primer, which can now be printed via a primer ink cartridge in products such as the Mimaki UJF-3042/6042 MkII, saving time and money and, once again, extending the number of substrates and objects that can be printed to.

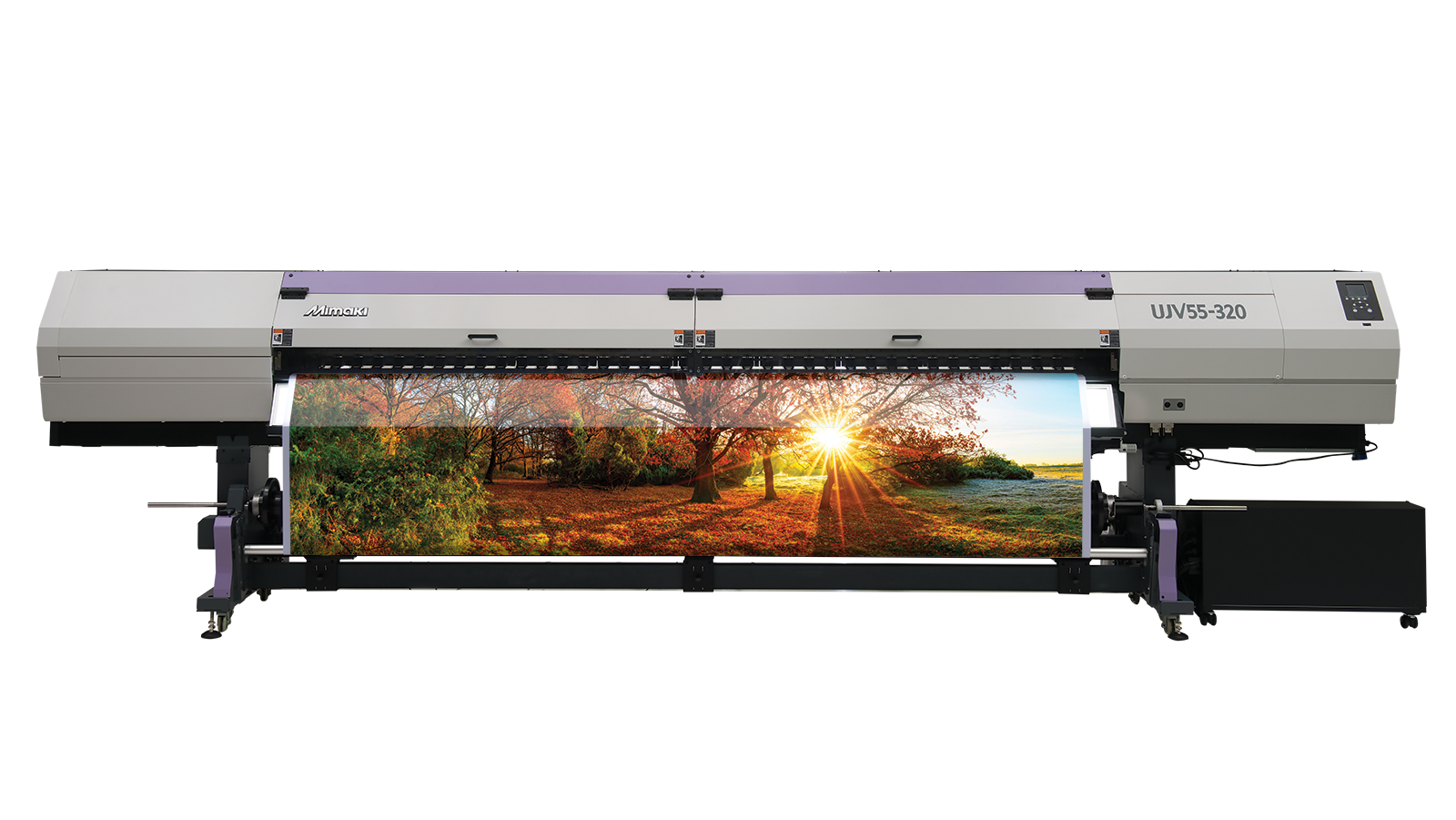

The thickness of the ink layer on the media is a key feature of UV curable ink, making it ideal for backlit signage where the ability to ‘block out’ areas of the back lighting improves the overall illuminated colour performance and vibrancy. For applications such as this, which are increasingly being used in exhibition halls and retail environments, the Mimaki UJV55-320; a 3.2m wide roll-to-roll UV printer, steps up to the mark with an in-line LED lightbox to enable backlit print inspection on the fly.

The ability to print to textile substrates is a key factor to the success of UV inks. There has been a dramatic rise in the use of textile applications across various industries. It’s a greener option both from a manufacturing and also a recycling perspective, it transports easily and is lightweight reducing those costs, plus it looks great and is far more tactile than a lot of standard substrates for sign and graphics.

All in all, UV ink offers sign and graphics providers an endless opportunity to provide ‘in demand’ applications to a number of industries. The combination of high-speed and versatile hardware, vibrant and effective UV inks and material technology that continues to offer something new and improved, means that getting into UV printing is a good option.