Moving Into Soft Signage

Sign Makers toying with the idea of moving into textile printing may find it easier than they think if they make the natural progression into soft signage.

Textile printing for clothing and accessories is a completely different market requiring specialist equipment and training, but there’s a buoyant market in soft signage and plenty of work to be found for a number of reasons.

Soft signage is tactile and is popular because of the great visual effects it offers as a signage option. It’s also lightweight, keeping transport costs low and keeping carbon footprints to a minimum. Textile substrates in general travel well; they don’t damage easily in production, in transit or in use, and are very easy to install and change as required.

Another benefit is that there’s a good chance that a print company’s existing customer base will require soft signage, so if a print provider hasn’t made the move to providing soft signage yet, they should consider it as a potentially profitable solution in order to avoid their customers looking elsewhere.

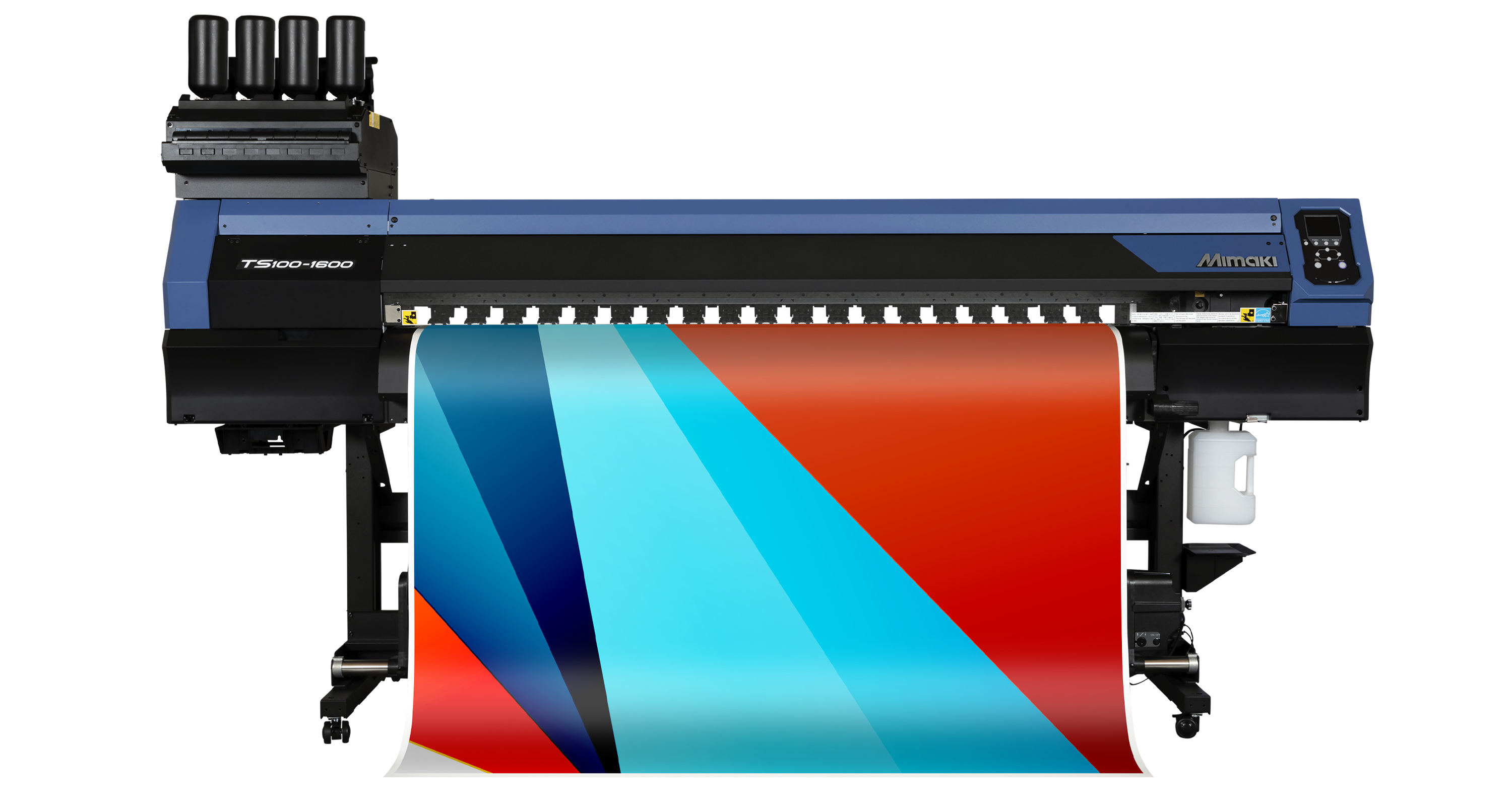

For soft signage that’s tactile in nature, such as flags, then it’s dye sublimation all the way. Direct dye sublimation hardware, such as Mimaki’s Tx300P-1800 provides high quality output on a wide variety of fabrics and with a selection of ink sets. Printing with dye sublimation inks onto polyester substrates at print speeds up to 68m²/hr makes this printer an ideal option for soft signage producers and is highly cost effective. The beauty of dye sublimation printed polyester is that the inks penetrate through giving even density each side and the finish is soft making it ideal for moving items, such as feather or teardrop flags.

If sign makers are looking for an all-encompassing solution for printing general signage and banners, but with the flexibility to print onto coated polyester, the Mimaki UJV55-320 is a smart option. This versatile 3.2m LED UV printer provides the perfect conditions for printing backlit applications, due to the vibrancy of Mimaki’s UV inks coupled with the in-line lightbox for proofing of backlit applications on the fly. The developments that material manufacturers have achieved and the advancements in polyester technology give great effects for sign and display when printed with LED UV curing inks.