Direct to Object Printing: How to Transition from Pad and Screen Printing to a Digital Workflow

Companies that print (so not necessarily ‘printing companies’, but manufacturers that have some element of printing in their workflow), are continuing to evolve their processes to incorporate, and benefit from digital print, rather than traditional techniques such as screen and pad printing.

Digital printing offers many advantages over screen and pad printing methods. These include low start-up costs, the ability to print short runs, the wide range of colours and photographic quality output that can be incorporated, and the capability to offer variable content without incurring additional costs. As Mimaki’s distributor for the UK and Ireland, we have helped countless businesses transition to more efficient, flexible, and productive workflows. Mimaki’s long heritage in high-quality, direct-to-object printing has consistently supported this transition over the last couple of decades. (Continues below…)

Best in class performance

Mimaki’s UJF A3 and A2 format UV printers offer best in class performance, ease of use and creativity. Cold cure LED UV technology enables users to print on almost any object, and proprietary features like ‘long drop mode’ allow the decoration or branding of rounded, dimpled, and uneven surfaces.

The A3 sized UJF-3042MkII e and A2 bed UJF-6042MkII e are Mimaki’s latest small format flatbeds. With their attractive price point and broad reaching capabilities, they find homes in a wide range of businesses. As a result, they provide a creative solution for promotional print companies and commercial printers looking to expand their offerings. Notable features include an opaque white ink for printing on coloured substrates and a clear varnish adds premium decorative finishes. Finally, a primer enables printing on even the most challenging materials.

Variable data printing

Mimaki’s RasterLink RIP software, supplied with the UJF printers, enables effortless incorporation of variable data into designs. This opens up the potential for producing a bed of personalised pens, or golf balls or awards. These can then share some similar elements, coupled with individual names or other bespoke details.

Delivering best-in-class productivity, the printer combines multiple ink layers in a single pass to incorporate numerous creative effects into designs. These include faux-frost effects on clear acrylic and textured elements that can reproduce Braille. It’s even possible to produce two-way graphics that appear differently from the front and back.

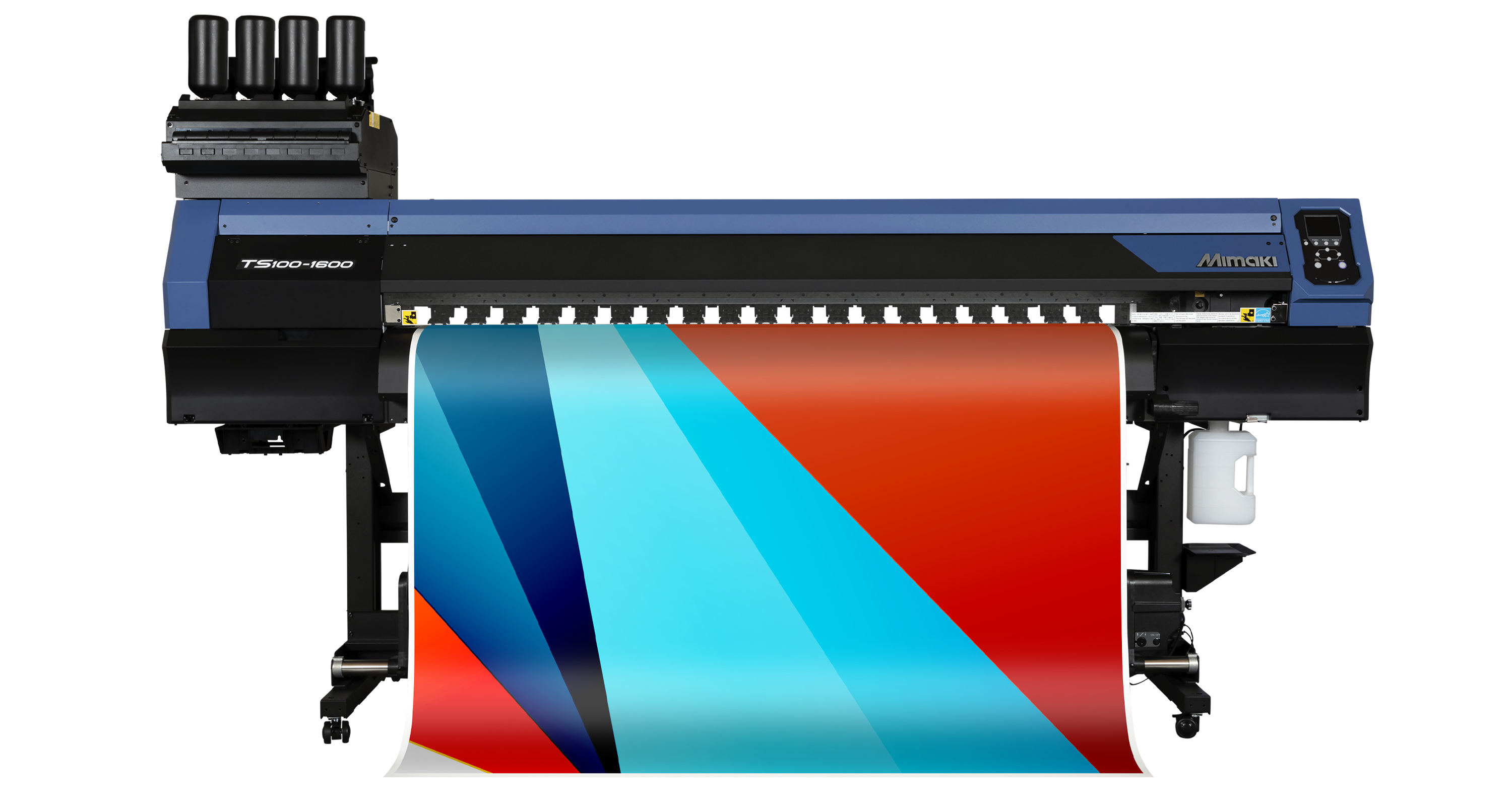

Mimaki has a substantial range of LED UV printers. These include grand format flatbeds, high production roll to roll machines and even integrated print and cut models. The small format UV printers share many of the technical and build quality features of Mimaki’s most industrial machines. As a result, these offer a strong investment for businesses that will rapidly appreciate the benefits of digital printing.