Consistency Wins The Day: Core Technologies for stable production

Mimaki’s Core Technologies are specifically engineered to assist the operator in two broad areas; ensuring stable production and delivering high image quality. A series of innovative and proprietary features safeguard productivity and provide a helping hand, right where it’s needed – at the heart of the production environment.

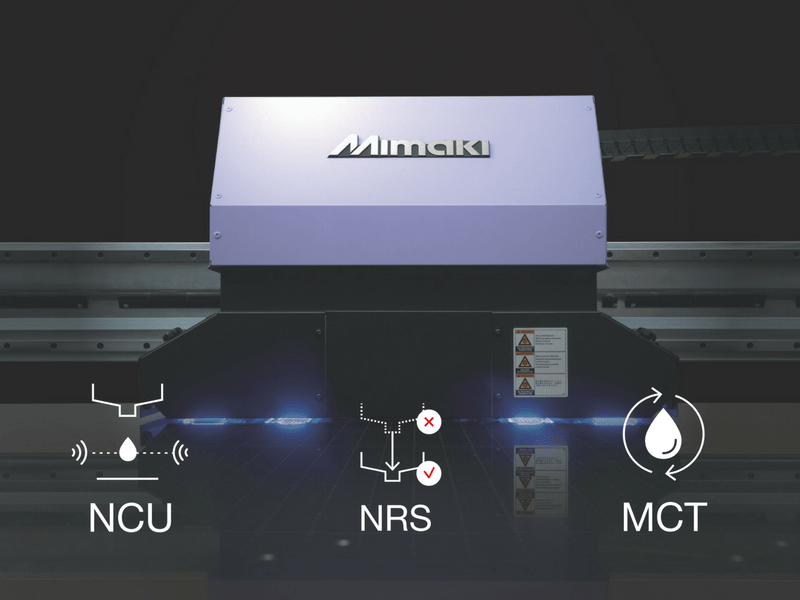

When the pressure is on, it’s invaluable to know that you’re being assisted by your print hardware in delivering spectacular quality output, on time and with the minimum of waste. Mimaki’s Core Technologies are built into the DNA of your printer, with features such as the Nozzle Check Unit (NCU) and Nozzle Recovery System (NRS) automatically checking, detecting and fixing printing issues on the head itself.

Being able to leave a print job running unattended frees up time for other jobs, increasing the overall productivity of the business. Having the NCU and NRS fail safe features mean that in the unlikely event of a nozzle dropping out during a long print run, the printer will stop printing, shortly recover and then continue with the job producing fantastic quality prints, saving time and material too.

Continuous operation is a major advantage for print businesses tasked with the challenges of hitting deadlines and getting print shipped on time, every time. It also frees up operators to run additional machines, serve customers or attend to other tasks, safe in the knowledge that their Mimaki is looking after itself.

As new features, such as white and silver ink are added to printers across the Mimaki range, so is the requirement to attend to the intricacies of maintaining the hardware when using such specialist inks. Mimaki Circulation Technology (MCT) is a perfect example of how a Core Technology has been developed to agitate the pigment in the white ink that features in numerous Mimaki printers, helping to stop problems before they even start. Where previously this was required to be performed manually, and therefore prone to being overlooked, it’s now carried out within the machine’s automatic workflow, ensuring continuous operation and stable production.

With every metre of material or litre of ink a valuable business cost, Mimaki’s Core Technologies save print companies money by minimising waste, as well as time and stress. Stable production results in reduced print errors and therefore faulty output – and when the job is correct first time around, it lessens the demands on deadlines and labour when it comes to finishing and preparing for despatch.