White ink acts as the foundation for your colours. Without it, designs printed onto dark or coloured garments will lose impact and clarity. Mimaki’s white DTF ink is engineered for excellent coverage and elasticity – ensuring colours appear bold and designs stay crack-free through repeated wear and washing.

Mimaki Tip

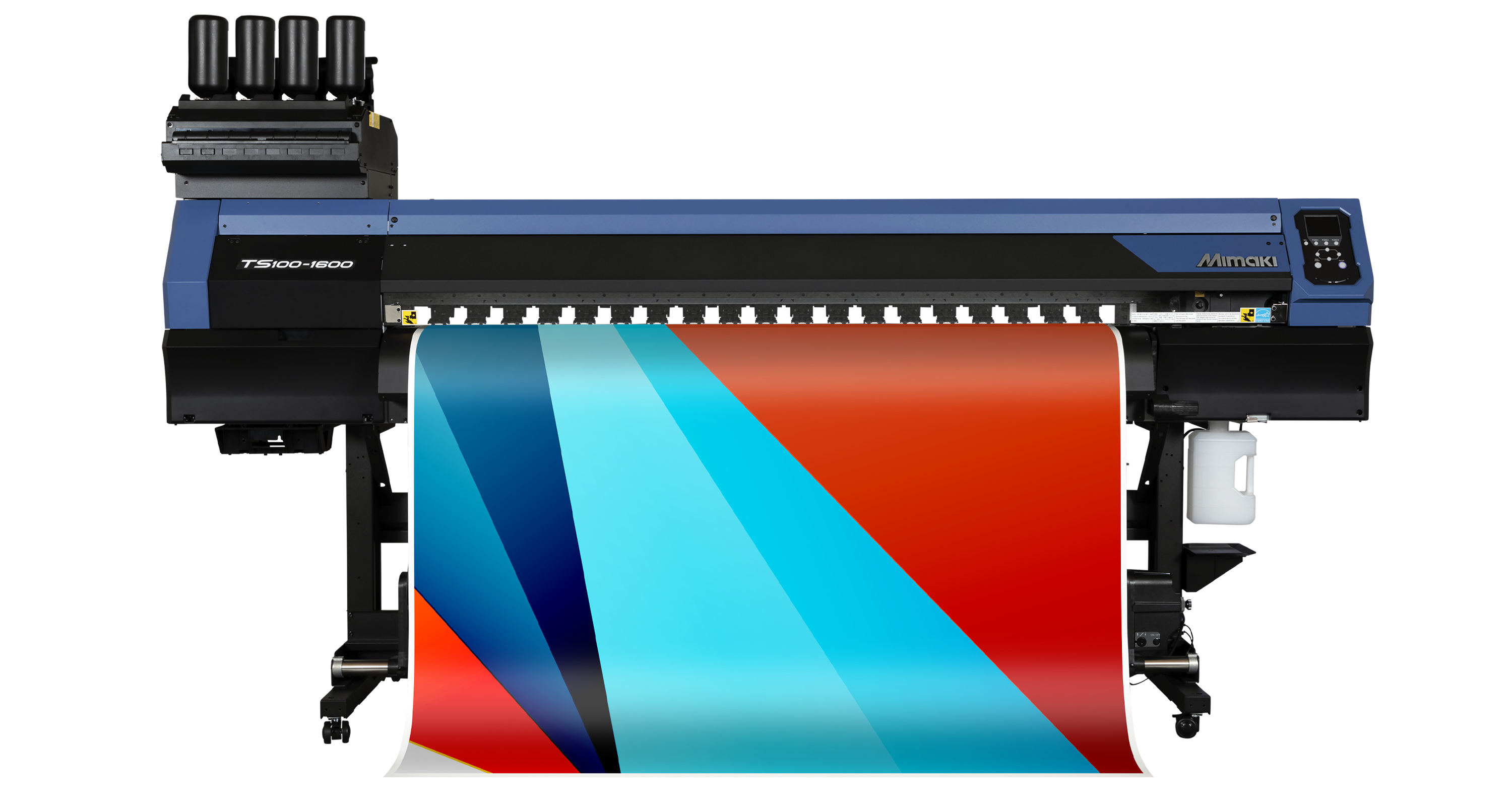

Use RasterLink RIP software to control white ink layering and ensure perfect alignment. With Mimaki’s ink and hardware combination, DTF printing is consistent, clean and commercially reliable.