Going Green with a bluesign® certification

Despite a growing commitment to sustainability, the textile industry remains one of the most polluted sectors globally. The extensive use of chemicals, water, and energy in textile manufacturing processes contributes significantly to pollution, waste, and carbon emissions. However, amidst these challenges, adopting green certifications has emerged as a crucial strategy for driving positive change.

Green certifications provide a framework for assessing and verifying environmental performance, encouraging companies to adhere to stringent sustainability standards. By obtaining reputable eco and sustainable certifications, companies active in the textile industry can demonstrate their commitment to reducing environmental impact, promoting transparency, and ensuring the welfare of workers throughout the supply chain.

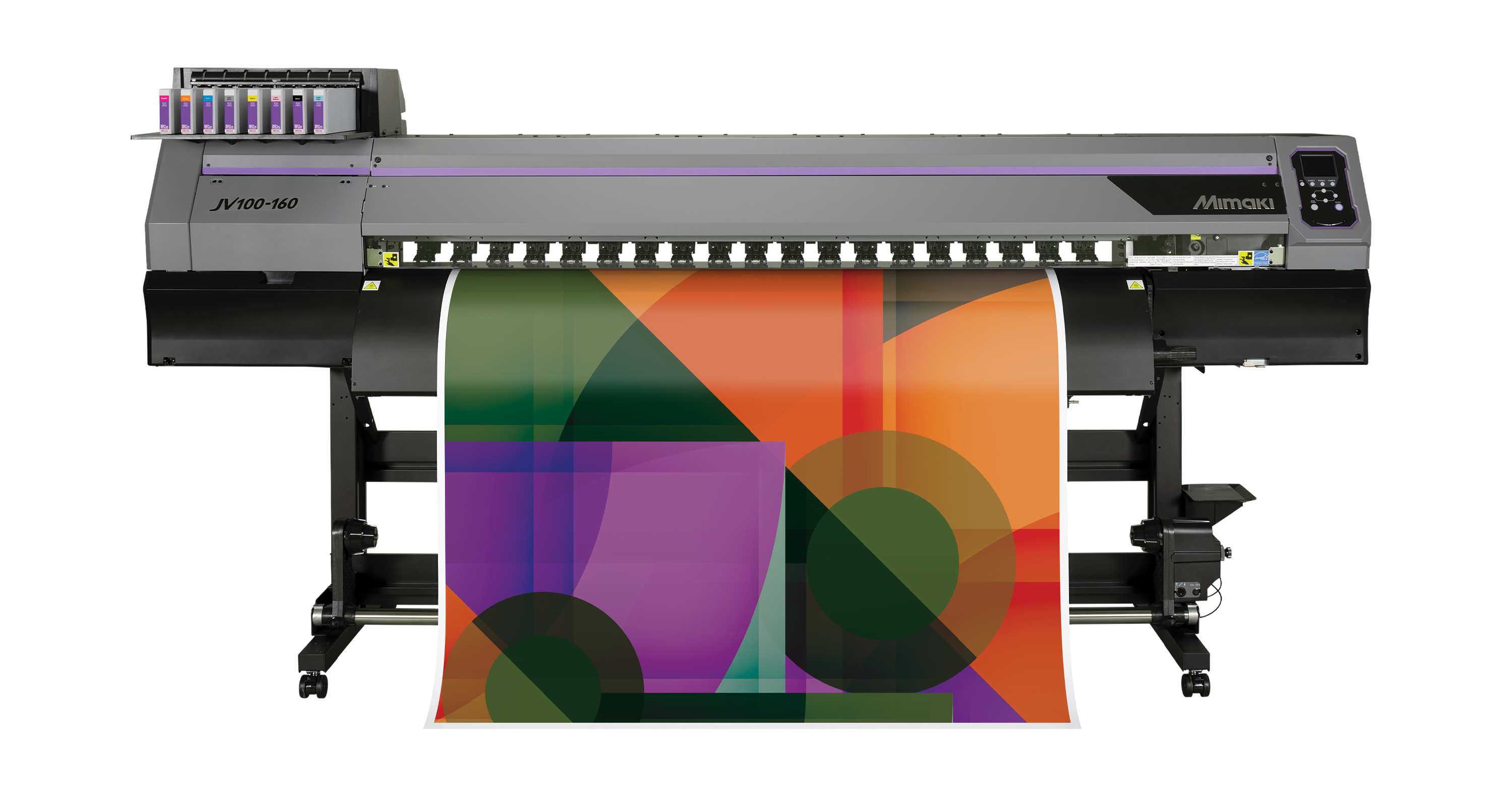

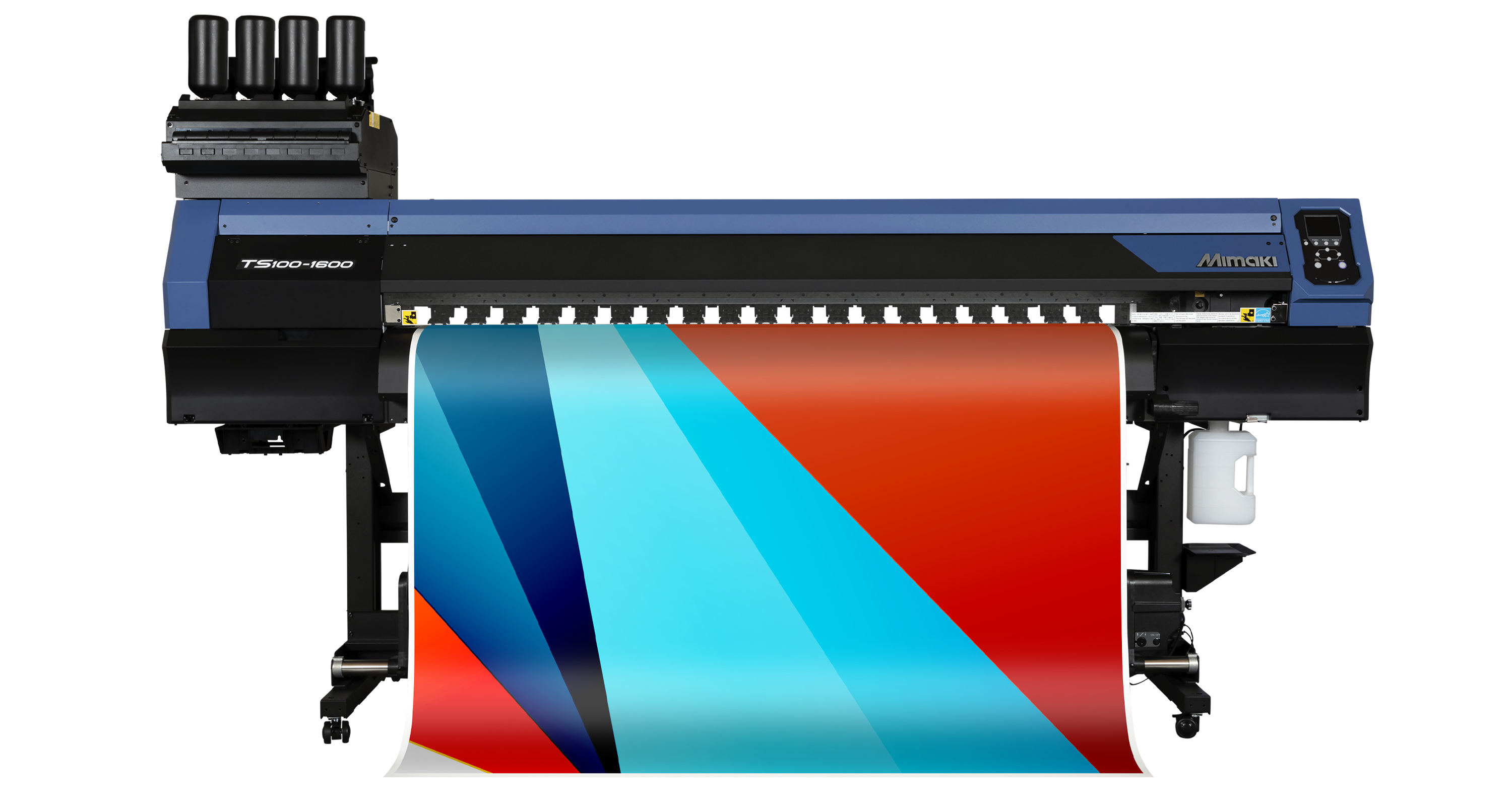

As part of a long-term strategy that sees the company committed to improving its sustainable footprint, Mimaki has recently achieved bluesign® approval for its dye-sublimation inks. This marks another milestone for the company, positioning Mimaki at the forefront of sustainable textile printing and enabling it to provide customers with a responsible choice, without compromising on quality or performance.

Becoming planet-certified

bluesign® is the most stringent sustainability certification in the textile industry. It goes beyond simply regulating harmful substances; it evaluates the entire production chain, from raw materials to finished products, ensuring responsible use of resources, minimal environmental impact, and worker safety.

Achieving the bluesign® approval positions Mimaki at the forefront of sustainable textile printing, and also validates the company’s long-term sustainability approach. Additionally, Mimaki’s bluesign® APPROVED dye sublimation inks meet the most stringent chemical management standards (ZDHC Level 3) for textiles. Being recognised within the ZDHC Chemicals to Zero Framework is also a testament to Mimaki’s strong commitment to sustainable development and careful management of chemicals.

So, what are the benefits for the textile industry of using Mimaki’s bluesign® APPROVED dye-sublimation inks?

- Reduced environmental impact: Choosing bluesign® APPROVED dye-sublimation inks is an effective and trusted way for textile producers to significantly reduce their environmental footprint. The use of approved inks and cutting-edge sublimation printing technologies can guarantee lower water consumption, reduced energy usage, as well as minimised CO2 emissions.

- Regulatory compliance to access major markets: As environmental concerns grow, so does the amount of stringent environmental regulations and the bluesign® certification can help meet those new rules. With leading textile brands demanding sustainable practices be a key part of production, Mimaki’s bluesign® APPROVED inks help textile companies unlock new partnerships with eco-conscious businesses.

- Improved brand image: As well as across businesses, consumers are also increasingly demanding sustainable products. The use of bluesign® APPROVED inks not only validates sustainable practices, but also empowers consumers to make informed choices, driving demand for eco-friendly products and incentivising further industry-wide improvements.

- Future-proof investment: Sustainability is not just a temporary concern. Given the damage already done to our planet, it is hard to envision a future where sustainability is not a top priority. By investing in bluesign® APPROVED inks now, brands are getting ahead of both market and regulatory trends of the future.

A bluesign® for a Green Future

To conclude, green certifications play a pivotal role in catalysing the transformation of the textile industry towards a more sustainable and responsible future. Choosing Mimaki’s bluesign® APPROVED inks is a trusted way of getting your sustainability goals on track. As a company that highly values sustainability, this approval represents a significant milestone in efforts to enhance the green performance of printing companies and ultimately help create a more sustainable textile printing industry.