Combining direct to object printing and laser cutting

Combining complementary tech can have many advantages. Diversifying your business by opening up new product lines, applications and opportunities, the right addition to your hardware quiver can also enable you to get more out of your existing equipment. A perfect example of this strategy is combining laser cutting with direct-to-object printing.

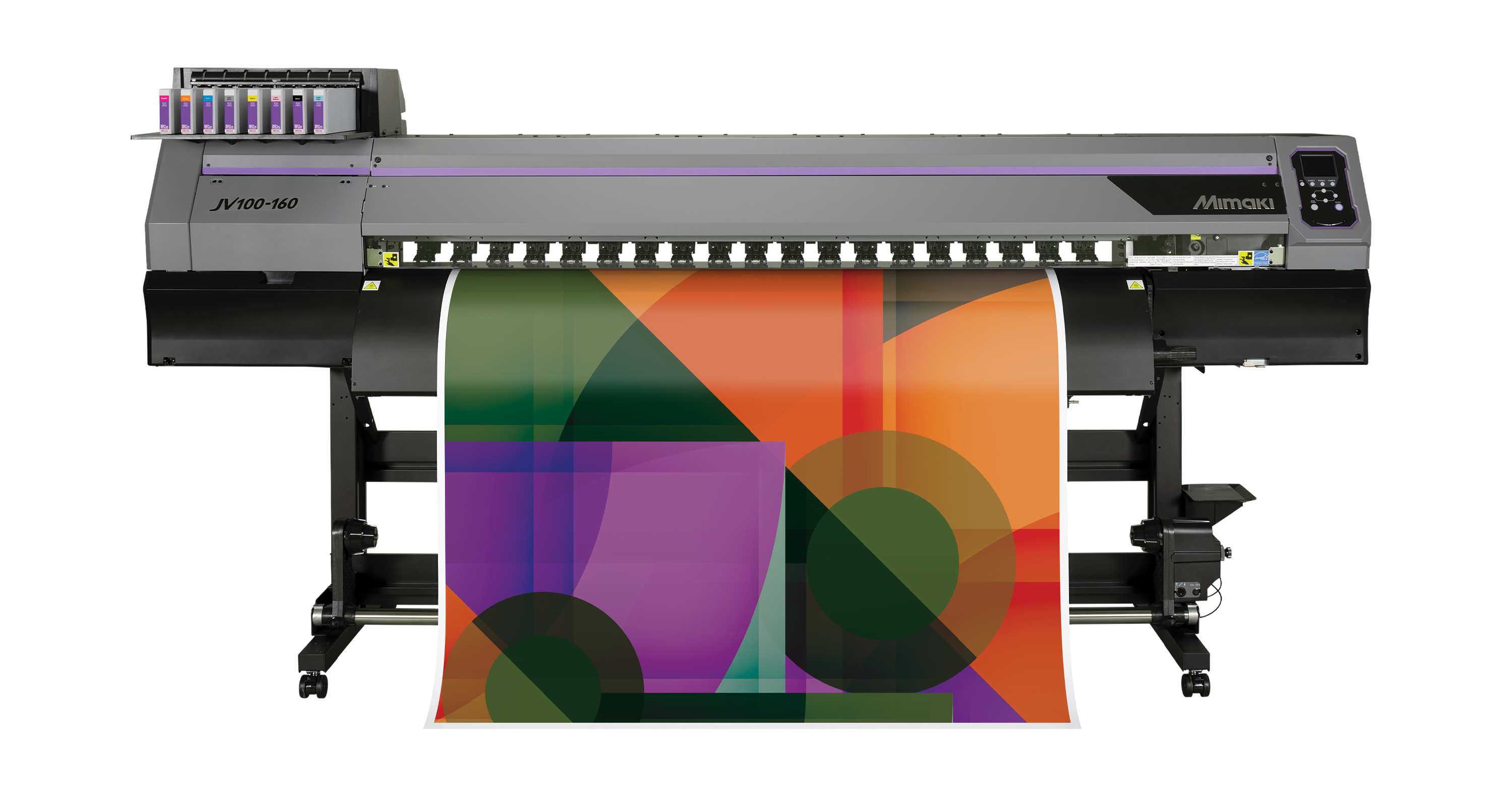

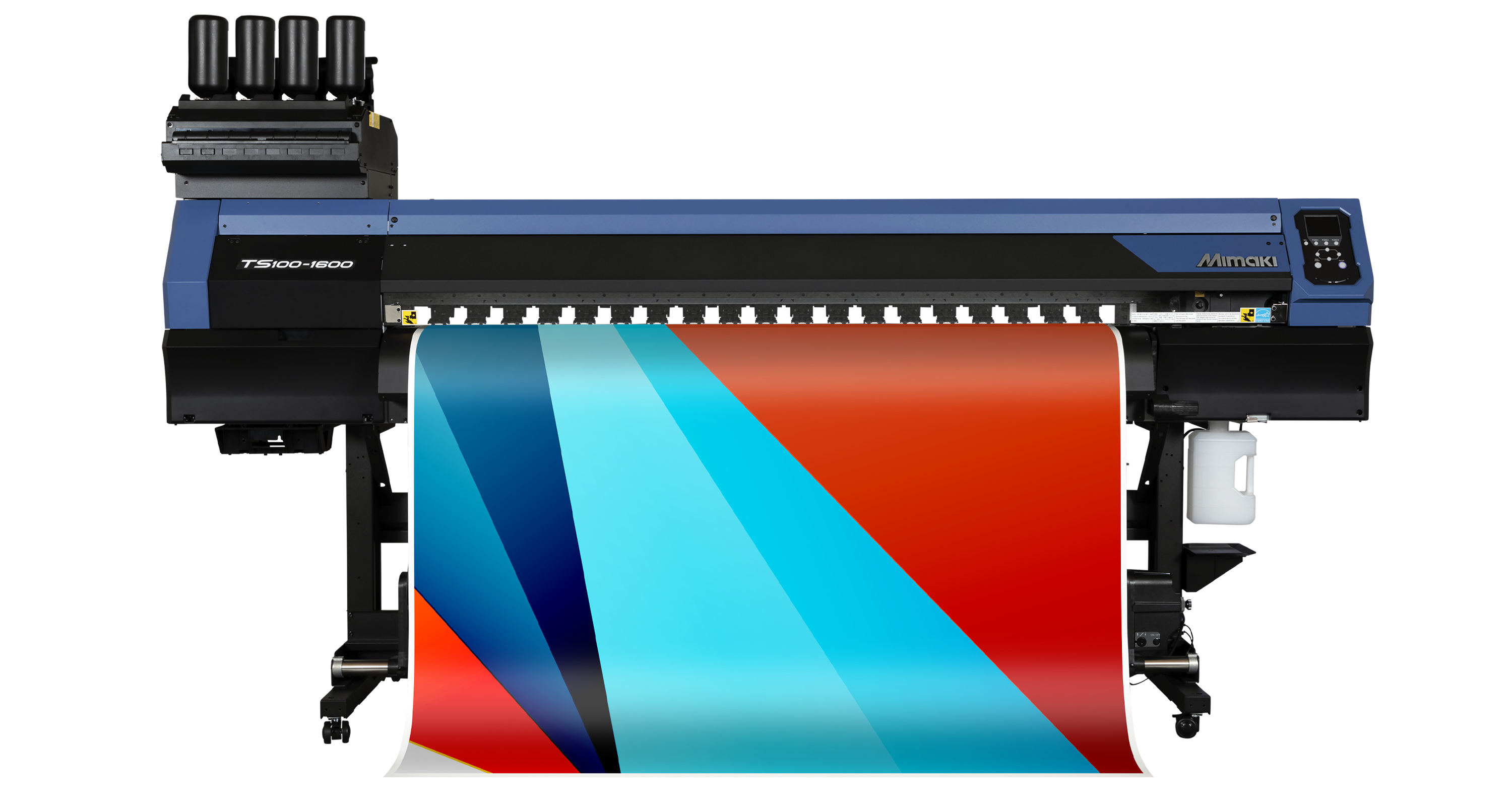

The Mimaki UJF Series is often regarded as the de facto range of direct-to-object printers. With multiple bed sizes, ink types and options to print onto almost anything, it delivers razor sharp, vibrant photo-quality output onto countless materials. Trotec’s range of laser cutters are capable of producing custom cut or engraved designs with pinpoint accuracy on a range of materials including acrylic, metal, card and wood.

By pairing these two technologies, printed output can be quickly cut into intricate shapes, and cut items can employ full colour decoration for branding, display or personalisation purposes. As applicable to the sign a display market as it is to the bespoke gifts, manufacturing and prototyping sectors, a combination of laser cutting and direct-to-object printing can add significant value to the end product.

Point of Sale

This short video highlights how the combination of a Mimaki UJF printer and a Trotec Speedy laser can be employed to decorate and customise not just the point of sale material, but the end product as well. In fact, even the jig for the phone cases was cut out by the laser!

Signs

With the ability to decorate an enormous range of materials, a neat tip is to try combining them to deliver really creative end results. In this film, we show you how two different materials: clear acrylic and wood – can work together to show off a business with an impressive new sign. Adding colour with the print and additional detail from the laser cutter elevates the work to a new level.

{snippet youtube|k4VcafBNNno}

Packaging & Promotional Materials

This final quick example demonstrates how direct printing onto packaging board can rapidly take a client design to prototype realisation, with additional elements onto acrylic utilised for product decoration. Showing off the flexibility of both the Mimaki and the Trotec, this project is a great demonstration of how value can be added with simple creativity and personalisation.

{snippet youtube|8p1k7AryCAs}

So, if you’ve got a laser cutter but not a printer, or vice versa, these examples should give you a good idea of how the two technologies can successfully complement each other and open up new opportunities for your business. If you’d like to discuss the technology further, we’d be delighted to help, and have a range of Mimaki flatbed LED UV printers at our disposal in our showroom, along with a Trotec laser cutter.