Lamination Q & A

Why is it so important for sign-makers to invest in quality lamination materials?

Over the years, we’ve all learnt the importance of lamination for certain print applications. However, if you were to speak to a graphics producer and ask them if they have a ‘laminator’ the answer may well be “No, but we have a ‘finishing machine’.” In other words, lamination is often seen as the process of finishing the print for any number of reasons but frequently, it’ll be in order to protect the graphics if it’s to be installed in a high-risk area, thus saving it from damage from adverse weather, chemical attack or mechanical abrasion.

What kind of an impact can quality lamination have on signage?

The key message is ‘finishing a print to ensure that its suitable for its application’. As well as the important aspect of protecting a print over lamination can also be used to change the way it looks, for example applying a matte laminate to reduce the reflection caused by interior lighting in a retail or exhibition environment.

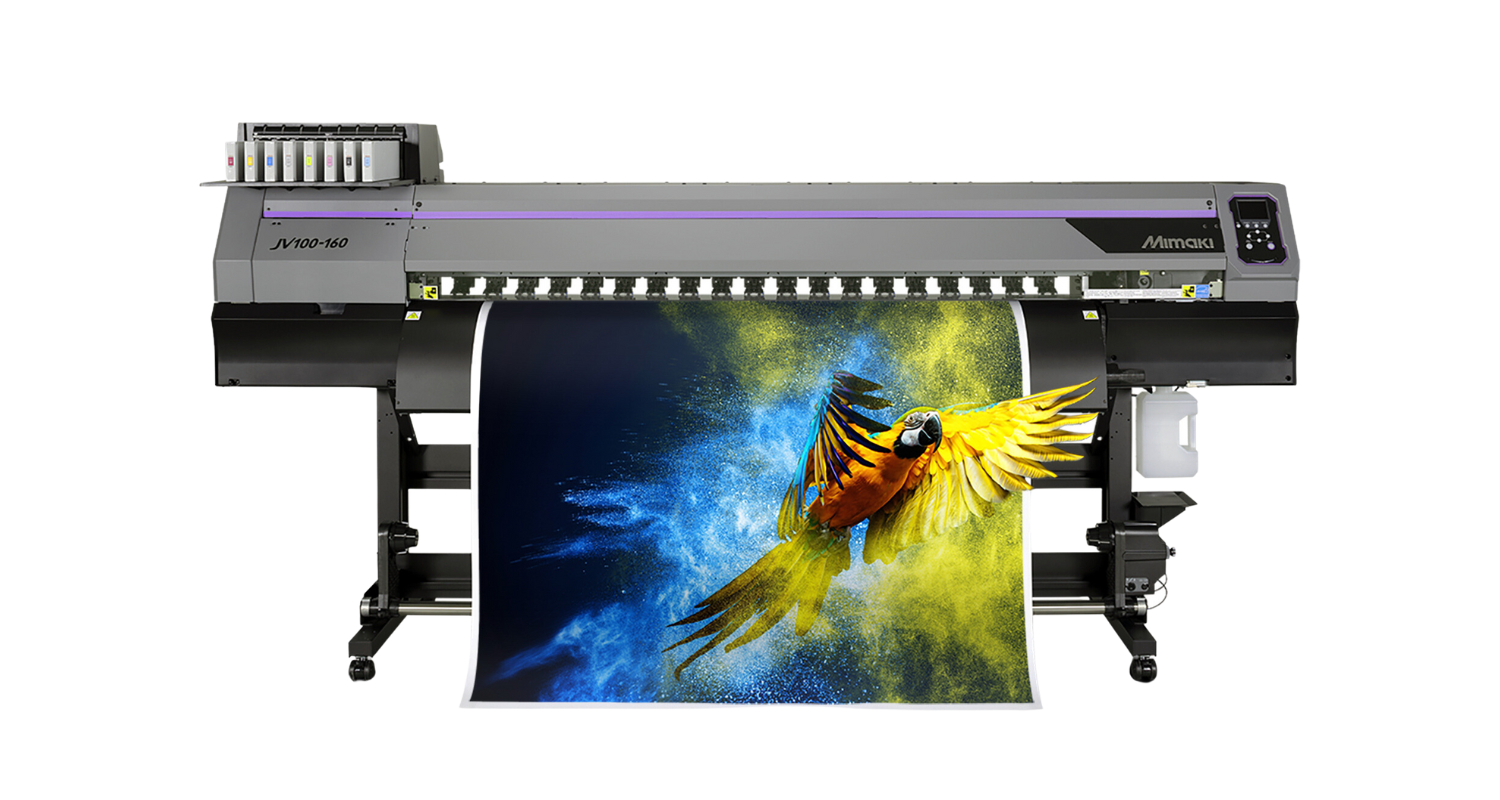

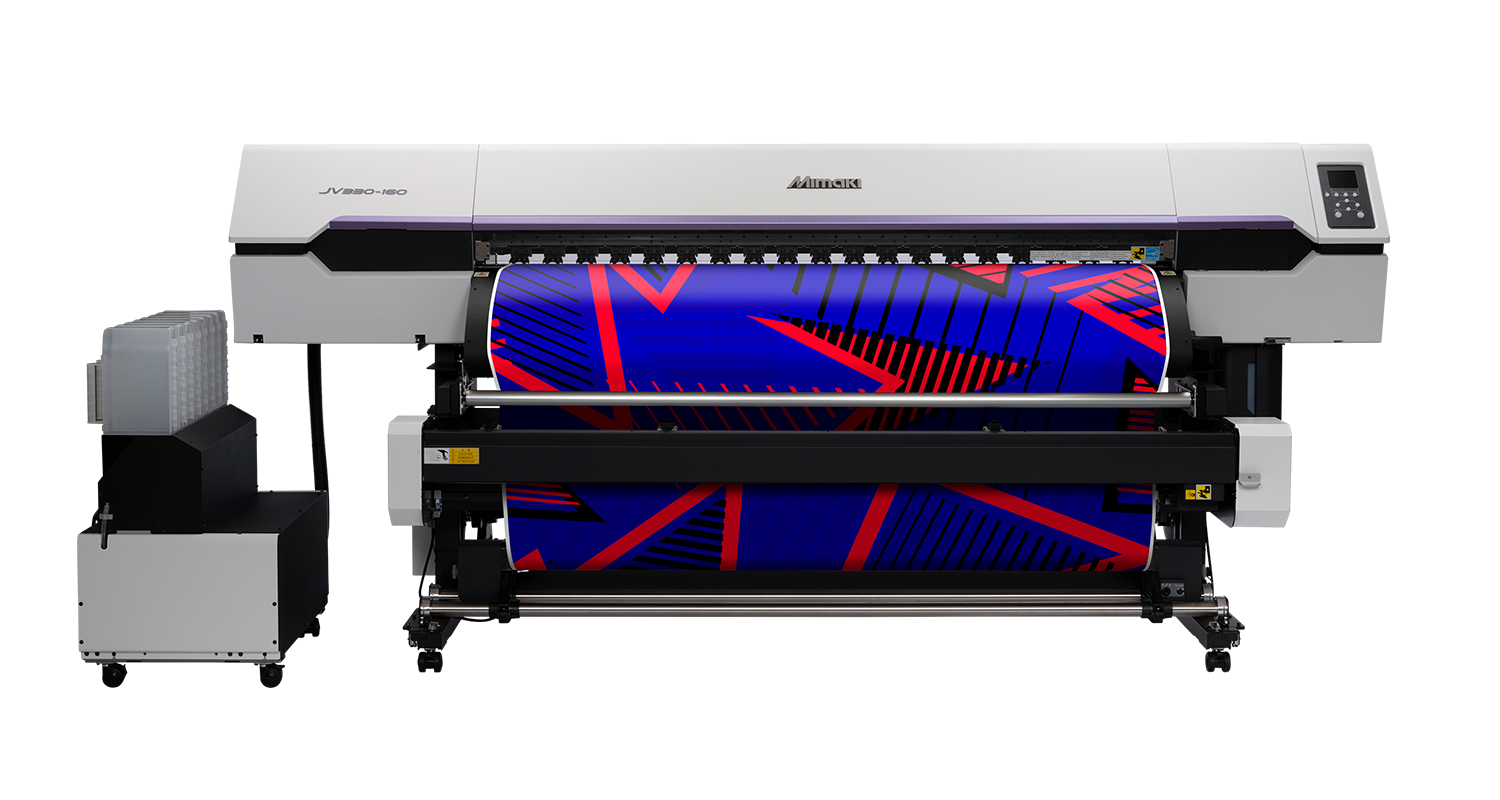

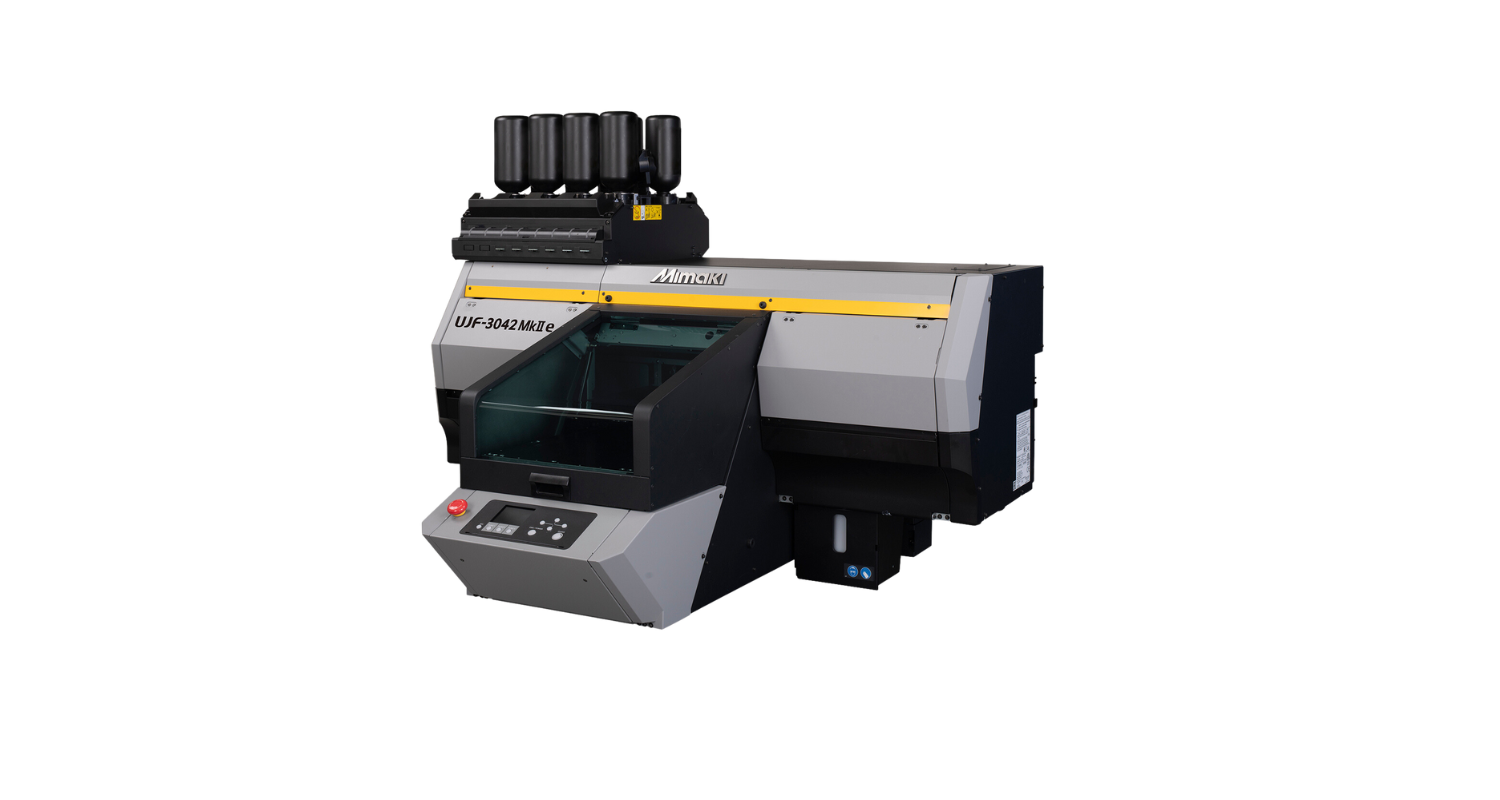

What are the latest lamination offerings from Mimaki?

Mimaki has recently launched a competitively priced laminator and matched film that’s specifically designed to partner with the exciting new Mimaki UCJV LED UV printer/cutter range. It’s a heat assist product that improves overlaminate film adhesion, particularly to surfaces printed with UV-curable inks. This reduces the potential for the ‘silvering’ effect created by pressure sensitive overlaminates. Due to instant curing, UV inks tend to have a slightly uneven surface which can trap air bubbles during the laminating process, causing silvery specs that can take away from the appearance of the product.

Mimaki UCJV prints are instantly dry meaning they can be immediately finished on a Mimaki LA Series laminator. This complete, harmonised solution ensures reliable performance and quality output for those occasions when a protective overlaminate is required.